Finding the right equipment is the most critical step in setting up a finishing line. The curing process determines the durability, look, and quality of the final product. Therefore, selecting the best powder coating oven manufacturers is not just about buying a machine; it is about finding a long-term partner for your production facility.

Many businesses struggle with uneven curing or high energy costs. These issues often stem from poor equipment design. Trusted powder coating oven manufacturers understand that temperature uniformity is key. Without precise heat distribution, the powder will not cross-link correctly.

This article breaks down what you need to know when evaluating suppliers. We will look at oven types, energy efficiency, and why HANNA stands out among global powder coating oven manufacturers.

The barrier to entry in manufacturing can be low, but the difference in quality is high. Experienced powder coating oven manufacturers know that airflow is everything. If the air inside the cabin is stagnant, you get cold spots. Cold spots lead to coating failure.

When you speak with powder coating oven manufacturers, ask about their airflow engineering. Top-tier builders use specific duct designs to ensure hot air reaches every part of the part. This is where brands like HANNA excel. They engineer systems that guarantee consistent results, batch after batch.

Another reason to choose established powder coating oven manufacturers is safety. Industrial ovens deal with high heat and often combustible gases. Reliable manufacturers strictly adhere to safety standards such as NFPA or CE regulations. You cannot afford to cut corners on safety.

Key Features Offered by Top Powder Coating Oven Manufacturers

Not all ovens are built the same. When comparing powder coating oven manufacturers, you need to look at the construction materials. A cheap oven uses thin sheet metal and poor insulation. This leaks heat and drives up your utility bills.

Premium powder coating oven manufacturers use tongue-and-groove insulated panels. These panels minimize thermal bridging. This keeps the heat inside the oven where it belongs. HANNA utilizes high-density rock wool insulation to ensure maximum thermal efficiency.

Control systems are another differentiator. Modern powder coating oven manufacturers integrate PLC controls with touch screens. This allows operators to save recipes for different parts. precise control over ramp-up times and soak temperatures is vital for quality control.

Batch Ovens vs. Conveyorized Systems

Most powder coating oven manufacturers offer two main categories of equipment: batch ovens and conveyorized ovens. Your choice depends on your production volume.

Batch ovens are ideal for lower volumes or large, heavy parts. Many powder coating oven manufacturers design these with walk-in capabilities. They allow for flexibility. You can cure a heavy steel frame in the morning and a rack of small aluminum parts in the afternoon.

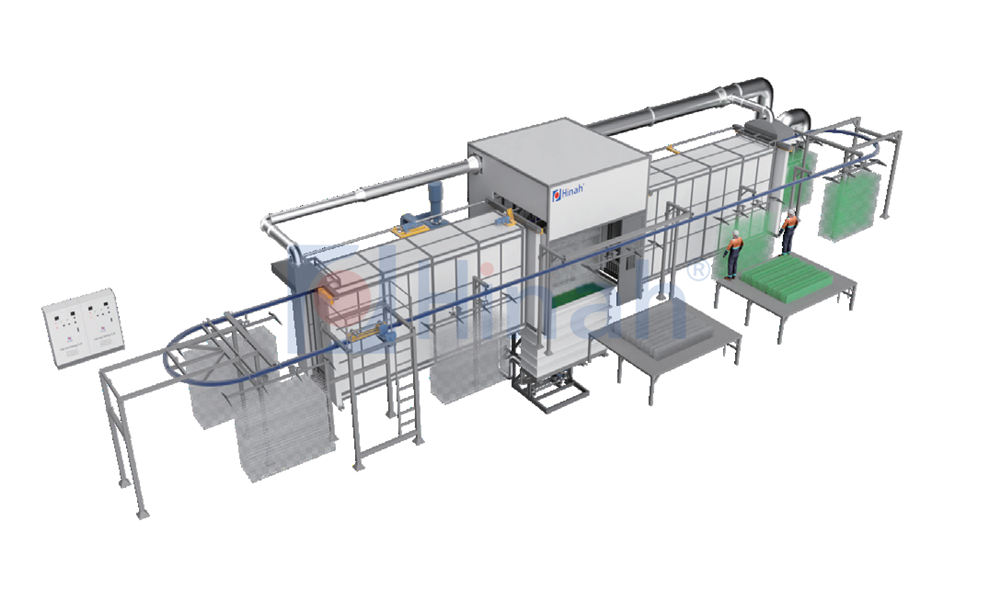

Conveyorized ovens are built for speed. Leading powder coating oven manufacturers design these for continuous production lines. The parts move through heat zones automatically. This reduces labor costs significantly. HANNA provides both solution types, tailored to the specific layout of your factory.

Energy Efficiency: A Priority for Powder Coating Oven Manufacturers

Energy costs are rising globally. This puts pressure on powder coating oven manufacturers to innovate. An inefficient oven can cost more to run in a year than its initial purchase price.

You should ask powder coating oven manufacturers about their burner efficiency. Direct-fired gas burners are usually the most efficient method for large ovens. They transfer heat immediately to the air stream.

However, some powder coating oven manufacturers also specialize in infrared technology. Infrared cures parts faster by heating the part surface directly. This can save time and energy for specific profiles. HANNA engineers often analyze your utility costs to recommend the most economical heating source, whether it is gas, electric, or infrared.

The Role of HANNA Among Powder Coating Oven Manufacturers

In the competitive landscape of powder coating oven manufacturers, HANNA has carved out a reputation for reliability. They do not just sell standard boxes; they provide engineered solutions.

HANNA distinguishes itself from other powder coating oven manufacturers through its focus on the "Delta T". This refers to the temperature difference across the part. HANNA designs guarantee that the top, bottom, and middle of your product reach the cure temperature simultaneously.

Furthermore, HANNA supports its clients globally. While some powder coating oven manufacturers disappear after the sale, HANNA prides itself on after-sales support. From installation guidance to spare parts, they maintain a relationship with the client.

Customization Capabilities of Powder Coating Oven Manufacturers

Every factory floor is different. Standard sizes often do not fit. This is why you need powder coating oven manufacturers who offer customization.

Perhaps you have a low ceiling or a tight corner. Competent powder coating oven manufacturers will design the ductwork and burner boxes to fit your space constraints. They can build top-mounted burner boxes to save floor space.

Customization also extends to the doors and flooring. Some powder coating oven manufacturers offer slotted roofs for overhead conveyors. Others provide flat floors for cart entry. HANNA works with your facility layout to ensure the oven fits perfectly into your workflow.

Evaluating the Durability of Equipment

Industrial equipment must withstand abuse. The best powder coating oven manufacturers build their frames with heavy-gauge steel. An oven needs to survive thousands of heat cycles. Expanding and contracting metal causes stress.

If powder coating oven manufacturers use weak frames, the oven will warp over time. This warping causes door seals to fail. Once the seals fail, you lose heat and money.

Check the door hardware used by powder coating oven manufacturers. HANNA uses explosion-proof latches and heavy-duty hinges. These small details ensure the longevity of the machine.

Airflow Design: The Secret Weapon

We mentioned airflow earlier, but it deserves its own section. It is the defining trait of elite powder coating oven manufacturers.

There are different airflow patterns: bottom-up, top-down, or cross-flow. Experienced powder coating oven manufacturers will recommend a pattern based on your parts. For example, complex parts with many cavities might need a different airflow than flat sheets.

HANNA utilizes advanced simulation software to predict airflow before the oven is even built. This separates them from powder coating oven manufacturers who rely on guesswork. Proper airflow ensures that powder does not blow off the part before it gels.

Maintenance Considerations

Even the best machines need maintenance. When interviewing powder coating oven manufacturers, ask about serviceability.

Are the fans easy to access? Is the burner accessible for tuning? Thoughtful powder coating oven manufacturers design their equipment with the maintenance team in mind.

HANNA places critical components in accessible areas. They also use standard components where possible. This means you do not always have to wait weeks for a proprietary part. This is a practical approach that many powder coating oven manufacturers overlook.

The Future of Curing Technology

Technology moves fast. Leading powder coating oven manufacturers are integrating Industry 4.0 features. This includes remote monitoring.

Imagine checking your oven temperature from your smartphone. Some powder coating oven manufacturers now offer systems that send alerts if the temperature drops. This prevents a whole shift of production from being wasted.

HANNA is at the forefront of this digital integration. They understand that modern factories need data. By collecting data on cure times and fuel usage, powder coating oven manufacturers help facility managers optimize their operations.

Selecting the Right Partner

Choosing between powder coating oven manufacturers is a big decision. You should look at their portfolio. Have they built ovens for your specific industry?

Ask for references. Reputable powder coating oven manufacturers are happy to let you talk to past clients. Ask those clients about reliability and support.

Price is important, but it is not everything. The cheapest option among powder coating oven manufacturers often costs the most in the long run due to downtime and defects. HANNA offers a balance of competitive pricing and premium engineering.

Common Mistakes Buyers Make

One common mistake is underestimating capacity. Buyers often choose smaller units to save money. However, specialized powder coating oven manufacturers will tell you that a cramped oven leads to poor curing.

Another mistake is ignoring the heat-up time. Ask powder coating oven manufacturers how long the oven takes to reach 200°C. A slow oven kills productivity.

Finally, do not overlook the warranty. Reliable powder coating oven manufacturers stand behind their work. HANNA provides clear warranty terms, giving you peace of mind.

The market is full of powder coating oven manufacturers, but they do not all offer the same value. Your curing oven is the heart of your finishing line. If it fails, production stops.

By focusing on airflow, energy efficiency, and construction quality, you can filter out the low-quality suppliers. Brands like HANNA represent the standard for reliability in this sector. They combine engineering expertise with practical, user-friendly designs.

Take the time to research. Talk to multiple powder coating oven manufacturers. Ask the tough technical questions. When you choose a partner like HANNA, you are investing in the quality of your finish and the future of your business.

Frequently Asked Questions (FAQ)

Q1: How do I determine the right size oven for my production?

A1: To find the right size, you must measure your largest part and the racking system. Powder coating oven manufacturers typically recommend adding at least 500mm of clearance on all sides (height, width, and depth) around the part to ensure proper airflow. Additionally, consider your production volume; if you have a high volume of small parts, a conveyorized system calculated by line speed and cure time is more accurate than simple dimensions.

Q2: Which heating source is better: Gas or Electric?

A2: This depends largely on your local utility costs and the size of the oven. Most powder coating oven manufacturers recommend gas (LPG or Natural Gas) for medium to large industrial ovens because it is generally cheaper to run and heats up faster. Electric ovens are usually preferred for very small batch ovens or where gas lines are not available, as they are 100% efficient but can have higher operating costs per hour.

Q3: What maintenance does a powder coating oven require?

A3: Routine maintenance is vital for longevity. Powder coating oven manufacturers suggest checking the burner filters and fresh air intakes weekly to prevent clogging. You should also inspect the door seals for wear and tear every month, as leaks cause temperature inconsistencies. Furthermore, checking the fan belts and lubricating motor bearings annually ensures the airflow system remains balanced and effective.

Q4: Can HANNA customize an oven to fit a unique factory layout?

A4: Yes, HANNA specializes in custom configurations. Unlike some powder coating oven manufacturers that only sell standard sizes, HANNA can engineer ovens with specific ductwork, unique door placements, or overhead slots for conveyor systems. They can design the unit to fit around building columns or within height restrictions to maximize your available floor space.

Q5: How important is temperature uniformity in curing?

A5: It is absolutely critical. If an oven does not have uniform temperature (usually within +/- 5°C), the powder coating may under-cure (leading to chipping) or over-cure (leading to brittleness and color shift). Reputable powder coating oven manufacturers like HANNA design their airflow circulation specifically to eliminate hot and cold spots, ensuring that every inch of the part receives the exact thermal energy required for a durable finish.