Selecting the right industrial oven is a critical decision in setting up or upgrading a powder coating line. The performance, efficiency, and longevity of your finishing process hinge on the equipment you choose. For businesses, this means the search for reliable powder coating oven manufacturers is more than just a purchase; it's an investment in quality and productivity. The market is filled with numerous powder coating oven manufacturers, each promising superior performance, making the selection process challenging. This guide aims to demystify the key factors you should consider, from technological innovations to cost considerations, helping you make an informed decision that aligns with your specific production needs.

Understanding the Core Technology: What Makes a Great Curing Oven?

At its heart, a powder coating oven is designed for one primary function: to cure the applied powder coating into a hard, durable, and uniform finish. This process involves elevating the part's temperature to a specific range for a precise amount of time. The expertise of powder coating oven manufacturers is evident in how they manage heat distribution, airflow, and energy efficiency.

There are two main types of ovens offered by industrial oven manufacturers:

Batch Ovens (Walk-in / Benchtop): Ideal for low-volume production, large or irregularly shaped parts, and job shops. They operate on a load-and-process cycle.

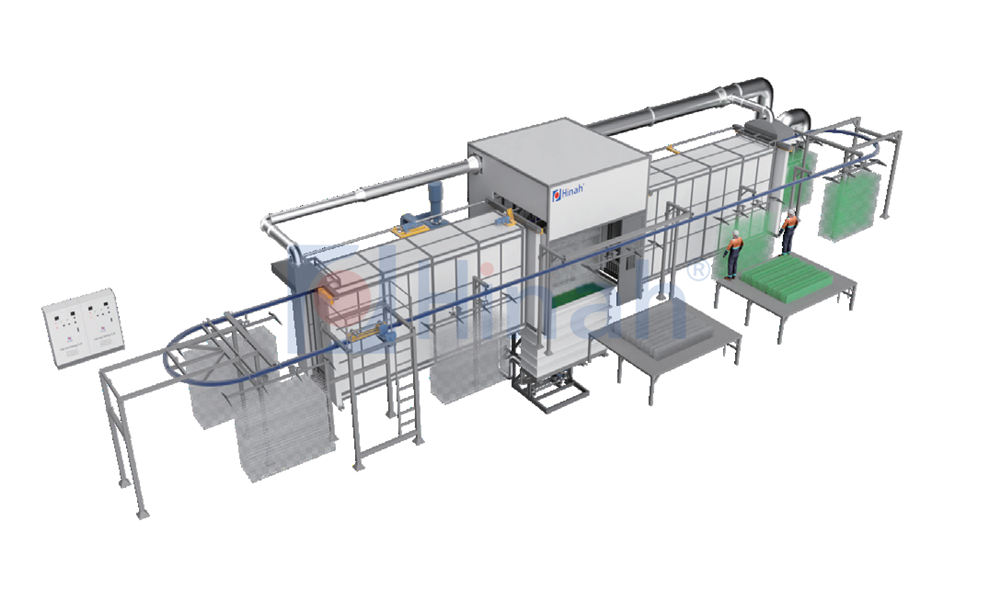

Conveyorized Ovens (Continuous): Suited for high-volume, continuous production lines. Parts are conveyed through the oven on a monorail or conveyor belt, allowing for a consistent and automated curing process.

The engineering behind these systems, including the type of heating (gas, electric, or infrared) and the airflow pattern (downdraft, updraft, or crossdraft), is where the technical prowess of powder coating oven manufacturers truly shines.

Key Factors to Consider When Evaluating Manufacturers

Not all powder coating oven manufacturers are created equal. Your choice will impact your daily operations for years to come. Here are the critical aspects to scrutinize.

1. Engineering Capabilities and Customization

The best powder coating oven manufacturers don't just sell standard models; they provide solutions. They should have a strong engineering team capable of designing an oven that fits your unique requirements. This includes considering your part size, production throughput, available floor space, and specific powder coating material's cure schedule. A manufacturer that offers a high degree of customization is often a safer bet than one with a rigid, one-size-fits-all catalog.

2. Build Quality and Materials

The durability of an oven is directly related to the materials used in its construction. Inquire about the thickness and type of insulation (e.g., fiberglass, mineral wool) and the gauge of the interior and exterior panels. High-quality industrial oven manufacturers use robust steel framing and panels designed to withstand high temperatures and the rigors of an industrial environment over many years, minimizing heat loss and improving energy efficiency.

3. Energy Efficiency and Operating Costs

With rising energy prices, the efficiency of your curing oven is a major contributor to your long-term operational costs. Leading powder coating oven manufacturers now focus heavily on designs that reduce energy consumption. Look for features like high-efficiency burners (for gas ovens), well-sealed doors and panels, advanced insulation, and heat recovery systems. An initially cheaper oven can become a financial burden if its operating costs are excessively high.

4. Safety Features and Compliance

Industrial ovens operate at high temperatures and must be designed with safety as a paramount concern. Reputable powder coating oven manufacturers build their units with comprehensive safety systems. These often include excess temperature controllers, air flow safety switches, emergency stop buttons, and properly rated explosion relief panels, especially important given the potential for powder fumes. Ensure the manufacturer complies with relevant industry standards and codes.

5. Reputation, Service, and Support

A manufacturer's reputation is built on the satisfaction of its past clients. Seek out reviews, case studies, and ask for references. Furthermore, the relationship doesn't end at delivery. The availability and quality of after-sales support, including installation supervision, operator training, and readily available spare parts, are hallmarks of a top-tier supplier. The best powder coating oven manufacturers stand behind their products with robust warranty terms and responsive technical support.

The Cost Equation: Investment vs. Long-Term Value

When requesting quotes from powder coating oven manufacturers, it's crucial to look beyond the initial purchase price. A low upfront cost might be tempting, but it could lead to higher expenses down the line through increased energy bills, frequent repairs, and premature failure. The concept of Total Cost of Ownership (TCO) is vital.

Initial Capital: The purchase price of the oven and installation.

Operational Costs: Ongoing energy, maintenance, and any required consumables.

Downtime Costs: Lost production due to equipment failure or inefficiency.

Investing in a well-engineered oven from a reputable manufacturer might have a higher initial cost but typically results in a much lower TCO due to superior efficiency, reliability, and durability.

The Selection Process: A Step-by-Step Approach

Define Your Needs: Document your part dimensions, production volume, cure schedule requirements, and available utilities (gas, electric).

Research and Shortlist: Identify a shortlist of powder coating oven manufacturers with proven experience in your industry or with similar applications.

Request Detailed Proposals: Provide your requirements and ask for detailed quotes, including specifications, layout drawings, and a clear breakdown of costs.

Ask the Right Questions: Inquire about build details, safety features, energy consumption estimates, and warranty.

Check References: Contact existing customers to learn about their experience with the equipment and the manufacturer's service.

Make an Informed Decision: Weigh the technical merits, TCO, and the manufacturer's reputation to select the best partner.

Choosing among the many powder coating oven manufacturers is a significant undertaking that demands careful research and a clear understanding of your operational goals. By prioritizing engineering quality, energy efficiency, safety, and strong manufacturer support, you can secure an industrial oven that not only meets your current production demands but also scales for future growth. This strategic investment will pay dividends in the form of consistent finish quality, reduced operating costs, and enhanced overall productivity for your powder coating operations.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for a custom powder coating oven from order to delivery?

A1: Lead times can vary significantly based on the complexity and size of the oven, as well as the current workload of the manufacturer. For standard models, it might be 8-12 weeks, while large, highly customized systems can take 16 weeks or more. It's essential to discuss timelines upfront with the powder coating oven manufacturers during the quoting process.

Q2: Can an existing oven be retrofitted or upgraded to improve its performance?

A2: Yes, in many cases, older ovens can be upgraded. Reputable industrial oven manufacturers often offer retrofit services that can include installing more efficient burners, adding better insulation, upgrading control systems to digital panels, or improving airflow systems. This can be a cost-effective way to enhance performance without the expense of a completely new unit.

Q3: What are the main advantages of electric ovens versus gas-fired ovens?

A3: Electric ovens are generally cleaner, as there are no combustion by-products, and they can be easier to install where gas lines are not available. They offer precise temperature control. Gas ovens, on the other hand, typically have much lower operating costs in regions where natural gas is inexpensive and are often preferred for high-volume production due to their rapid heat-up and recovery times.

Q4: How important is the control system on a powder coating curing oven?

A4: The control system is critically important. Modern digital controls allow for precise setting and monitoring of temperature and cure time, which is essential for achieving a consistent, high-quality finish. Features like data logging, recipe storage, and remote monitoring can significantly enhance process control, repeatability, and troubleshooting capabilities.

Q5: What kind of preventative maintenance is required for a powder coating oven?

A5: Regular maintenance is key to longevity and efficiency. A basic schedule includes periodic inspection and cleaning of the burner assembly (for gas ovens), checking and calibrating temperature sensors, ensuring all safety devices are functional, cleaning the fan blades and air filters to maintain proper airflow, and inspecting door seals for any leaks. The manufacturer should provide a detailed maintenance checklist.