Space is often the most expensive asset in a workshop. For custom coaters, wheel refurbishers, and lab testing facilities, a massive conveyor line is not practical. This is where a small powder coating booth becomes the most valuable piece of equipment in the shop. It allows businesses to produce high-quality finishes without dedicating their entire floor plan to the process.

Many operators underestimate the engineering required for these compact units. They assume smaller size means lower technology. That is a mistake. A well-engineered small powder coating booth must manage airflow, filtration, and lighting just as strictly as a large industrial line.

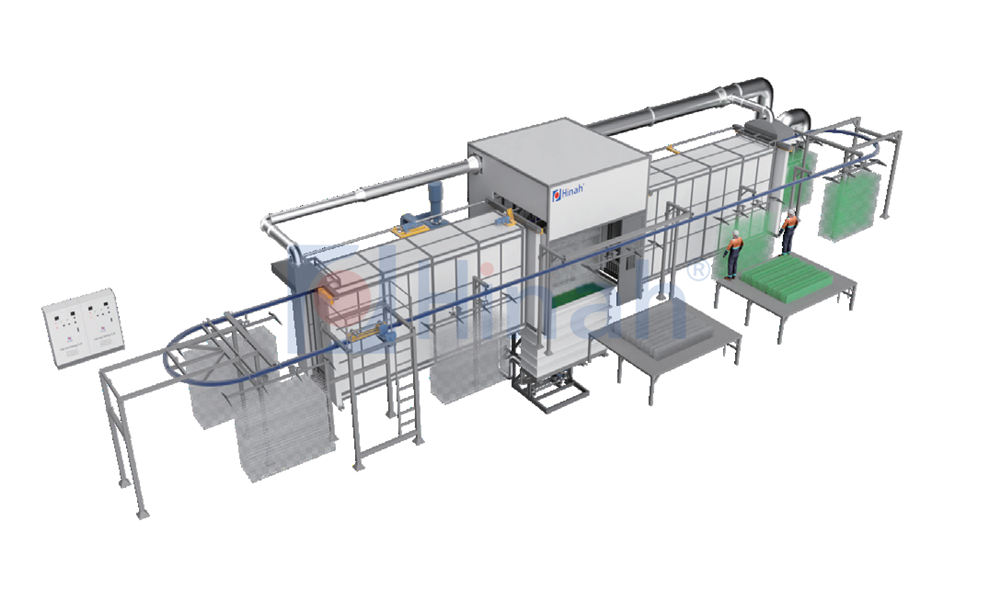

If you are looking to upgrade your current setup or start a new batch coating line, selecting the right equipment is vital. This article examines the benefits, features, and technical considerations of investing in a small powder coating booth, with a focus on the reliability offered by HANNA.

The Rising Demand for the Small Powder Coating Booth

The finishing industry has shifted. High-volume runs are still common, but there is a massive surge in "high-mix, low-volume" production. Custom car shops need to coat four rims in a specific candy color. Prototyping firms need to finish five brackets for a client review. These scenarios require the flexibility of a small powder coating booth.

A dedicated small powder coating booth allows for rapid color changes. In a large system, changing colors can take an hour or more. In a compact open-face booth, you can switch from black to red in minutes. This agility allows shops to take on more diverse jobs.

Furthermore, the initial investment is lower. New businesses can enter the market with a professional small powder coating booth without taking on massive debt. It lowers the barrier to entry while maintaining professional standards.

Design Features of a HANNA Small Powder Coating Booth

When you buy a booth, you are buying airflow. HANNA understands this principle better than most. A HANNA small powder coating booth is designed to keep the powder contained. If the airflow is too weak, powder drifts into the shop. If it is too strong, it pulls powder off the part before it sticks.

HANNA engineers these booths with a specific face velocity. This ensures that the overspray is pulled gently but firmly into the filters. This balance is difficult to achieve in a small powder coating booth because the working area is tight. Turbulence can be a major issue in poorly designed units.

Another design feature to look for is the material. A small powder coating booth made from galvanized or stainless steel is far superior to painted mild steel. Powder is abrasive. Over time, it wears down surfaces. HANNA uses high-quality materials that resist corrosion and are easy to wipe down during cleanup.

Filtration Systems in a Small Powder Coating Booth

The heart of any booth is the recovery module. In a small powder coating booth, you typically rely on cartridge filtration. These cylindrical filters capture the overspray. The air is then returned to the shop, clean and safe.

Cheap booths use standard paper filters. These clog quickly. A professional small powder coating booth uses polyester or nano-fiber filters. These materials trap tiny particles but allow air to pass through freely. This maintains steady suction pressure.

HANNA incorporates pulse-jet cleaning systems even in their smaller units. A blast of compressed air knocks the powder off the filter and into a collection tray. This feature extends the life of your filters. It ensures that your small powder coating booth performs as well at the end of the shift as it did at the beginning.

Efficiency and Color Change in a Small Powder Coating Booth

Time is money. In a job shop, you cannot afford to spend an hour cleaning a small powder coating booth. The design must facilitate speed. Smooth internal walls are essential. If a booth has seams, bolts, or ledges on the inside, powder will accumulate there.

Leading manufacturers like HANNA design their small powder coating booth interiors to be flush. This means an operator can use a squeegee or compressed air to clean the walls rapidly.

The recovery drawer is another factor. It should be easy to remove and dump. Some users of a small powder coating booth spray to waste, meaning they throw the powder away. Others want to reuse it. HANNA designs give you the option to reclaim powder if the batch size justifies it, adding versatility to the small powder coating booth.

Safety Considerations for Your Small Powder Coating Booth

Powder coating involves fine dust. This dust can be combustible. Even a small powder coating booth must adhere to safety regulations. You need proper grounding. The booth chassis must be connected to an earth ground to prevent static buildup.

Lighting is another safety and quality factor. You cannot paint what you cannot see. A small powder coating booth can be dark if the lighting is poor. HANNA utilizes explosion-proof LED lighting. This provides bright, clear light that mimics daylight. It helps the coater see into corners and Faraday cage areas.

Ventilation is also key. While the filters catch the dust, the small powder coating booth returns air to the room. If the filters fail, you need a backup plan. Reliable systems have pressure gauges that alert the operator when filters are blocked or damaged.

Ideal Applications for a Small Powder Coating Booth

Who benefits most from this equipment? The automotive aftermarket is a huge user. A small powder coating booth is the perfect size for brake calipers, valve covers, and wheels.

Laboratory and testing facilities also rely on them. Before a chemical company produces tons of powder, they test small batches. They need a small powder coating booth to spray test panels. These panels are used to check for color match, gloss, and durability.

General job shops often install a small powder coating booth as a secondary line. They keep their main line running black or white, and use the small booth for custom colors. HANNA often supplies these "offline" booths to large factories to handle rush orders or samples without disrupting mass production.

Energy Consumption and Operating Costs

A massive benefit of a small powder coating booth is energy efficiency. Moving air takes power. A large room-sized booth requires massive fans and motors, often 10HP or more. A small powder coating booth might only need a 2HP or 3HP motor.

This difference in electricity usage adds up over a year. Additionally, because the small powder coating booth recycles air back into the shop, you do not lose heated or cooled shop air. Venting air outside is like throwing money out the window in winter.

HANNA optimizes the fan efficiency in their small powder coating booth models. They use high-efficiency impellers that move more air with less energy. This lowers your monthly overhead, making the small powder coating booth a smart financial choice for lean operations.

Installation and Maintenance of a Small Powder Coating Booth

One of the selling points of a small powder coating booth is ease of installation. Many units ship fully assembled or in large modules. You do not need a construction crew to set one up.

You simply need a level floor, a power connection, and a compressed air line. HANNA provides clear schematics to make this process simple. However, placement matters. You should place the small powder coating booth away from grinding areas or open doors where drafts could disturb the airflow.

Maintenance is straightforward but necessary. Daily checks of the collection tray are required. Weekly inspections of the filters in your small powder coating booth prevent failures. If you neglect the filters, the fan has to work harder, which can lead to motor burnout.

Why HANNA Stands Out in the Market

There are many generic suppliers of finishing equipment. However, HANNA brings engineering expertise to the small powder coating booth market. They do not treat these small units as an afterthought.

HANNA applies the same airflow simulation technology used in their massive automotive lines to their small powder coating booth designs. This ensures professional results. They understand that a small shop cares about quality just as much as a large factory.

Furthermore, HANNA offers support. If you have a question about airflow settings or filter replacements for your small powder coating booth, their team is available. This after-sales support is rare in the market for compact equipment.

Customization Options for a Small Powder Coating Booth

Sometimes "standard" does not fit. You might have a part that is long and narrow. HANNA can modify the dimensions of a small powder coating booth to suit your needs.

You might need a pass-through slot for an overhead track. Even in a small powder coating booth, manual conveyors are common. HANNA can cut the roof slots and provide the necessary sealing brushes to keep the dust in.

Control panels can also be customized. Some users want simple On/Off switches. Others want VFDs (Variable Frequency Drives) to control the fan speed of their small powder coating booth. HANNA can accommodate these technical requests, ensuring the operator has full control over the finishing environment.

Troubleshooting Common Issues

Operators sometimes face issues with a small powder coating booth. The most common is "blowback." This happens when the filters are clogged. The air has nowhere to go, so it pushes back into the booth face. Replacing the filters usually solves this.

Another issue is poor lighting. Over time, clear covers over lights get coated with dust. In a small powder coating booth, this dramatically reduces visibility. Regular cleaning of light fixtures is a must.

Static charge can also be a problem if the small powder coating booth is not grounded. If the part doesn't attract powder, check the ground clamp. HANNA systems emphasize robust grounding points to eliminate this variable.

Making the Final Decision

Investing in a small powder coating booth is a commitment to quality. It moves you away from "backyard" spraying into professional finishing. It provides a clean, safe, and controlled environment for applying powder.

When you look at the ROI, a small powder coating booth pays for itself quickly through material savings and reduced rework. You waste less powder because the recovery system captures it. You have fewer rejects because the airflow keeps dust away.

HANNA offers a range of options that balance price and performance. Their reputation in the global market makes them a safe bet for any business looking for a reliable small powder coating booth.

The finishing industry is competitive. To succeed, you need equipment that works every time. A small powder coating booth is the versatile workhorse of the modern coating shop. It handles samples, custom parts, and short runs with ease.

By choosing a reputable manufacturer like HANNA, you ensure that your small powder coating booth is built to last. From the steel gauge to the filter quality, every detail matters. Do not compromise on your equipment.

Whether you are starting a new business or expanding your capabilities, a small powder coating booth is the right tool for the job. It saves space, saves energy, and delivers the professional finish your customers expect.

Frequently Asked Questions (FAQ)

Q1: What are the power requirements for a typical small powder coating booth?

A1: Most units run on standard industrial power. A small powder coating booth usually requires a 3-phase connection for the fan motor, typically 220V or 380V depending on your region. However, some very small hobbyist units can run on single-phase power. HANNA can configure the electrical components to match your facility's available power supply.

Q2: Can I recycle powder with a small powder coating booth?

A2: Yes, but it depends on your color usage. If you spray one color for a long time, you can collect the powder from the tray or bin below the filters and sieve it for reuse. If you change colors frequently, most operators using a small powder coating booth will "spray to waste" because cleaning the filters perfectly for reuse takes too much time.

Q3: How often should I change the filters in my small powder coating booth?

A3: This depends on production volume. In a busy shop, you might change them every 6 to 12 months. If the small powder coating booth has a pulse-jet cleaning system, the filters last much longer. You should monitor the pressure gauge; when the pressure differential gets too high, it is time to change the cartridge.

Q4: Does HANNA provide installation services for a small powder coating booth?

A4: HANNA provides comprehensive installation manuals and remote support, which is usually sufficient for a small powder coating booth as they are often plug-and-play units. For larger or more complex custom setups, they can arrange for technicians or provide detailed guidance to your local contractor to ensure the airflow is calibrated correctly.

Q5: What is the difference between a cartridge booth and a cyclone booth?

A5: A cartridge booth (common for a small powder coating booth) captures powder directly into the filters. It is compact and efficient but slower to clean for color changes. A cyclone system separates powder using centrifugal force before it hits the filters, making color changes faster. Cyclone systems are typically larger and more expensive, so they are less common in the "small" category unless high-frequency color changes are required.