When it comes to establishing or upgrading a finishing line, the heart of the operation often lies in the curing process. Selecting the right equipment is paramount, and it begins with understanding the role of specialized powder coating oven manufacturers. These companies don't just build boxes that get hot; they engineer the critical component that ensures durability, quality, and efficiency in your powder coating manufacturing process. This article delves into the ecosystem of powder coating, the importance of the oven, and how to find the right partners for your business needs.

The Foundation: Understanding Powder Coating Manufacturing

Powder coating manufacturing is a multi-stage process that transforms raw metal into a finished, durable product. It's a dry finishing process where a free-flowing, thermoplastic or thermoset powder is applied to a surface, primarily metal. The key stages include pre-treatment (cleaning and preparing the surface), application of the powder via an electrostatic spray gun, and finally, curing the coating in a high-temperature oven. This final curing stage is where the magic happens: the heat causes a chemical reaction that cross-links the powder particles, forming a smooth, hard, and uniform film that is far more resilient than traditional liquid paints. The efficiency and effectiveness of this entire operation are heavily dependent on the quality of the powder coating systems in place, with the oven being the most critical thermal component.

Why Metal? The Perfect Union of Powder Coating on Metal

The process is exceptionally well-suited for powder coating on metal. The electrostatic application ensures the powder particles are attracted to the grounded metal part, leading to high transfer efficiency and minimal waste. More importantly, metals can withstand the high temperatures required for curing, typically between 325°F and 400°F (160°C - 205°C). This combination results in a finish that is highly resistant to chipping, scratching, fading, and wearing, making it ideal for everything from automotive parts and household appliances to architectural aluminum and industrial machinery. The success of applying powder coating on metal hinges on a oven that provides consistent, uniform heat to achieve a complete cure across the entire part, regardless of its geometry.

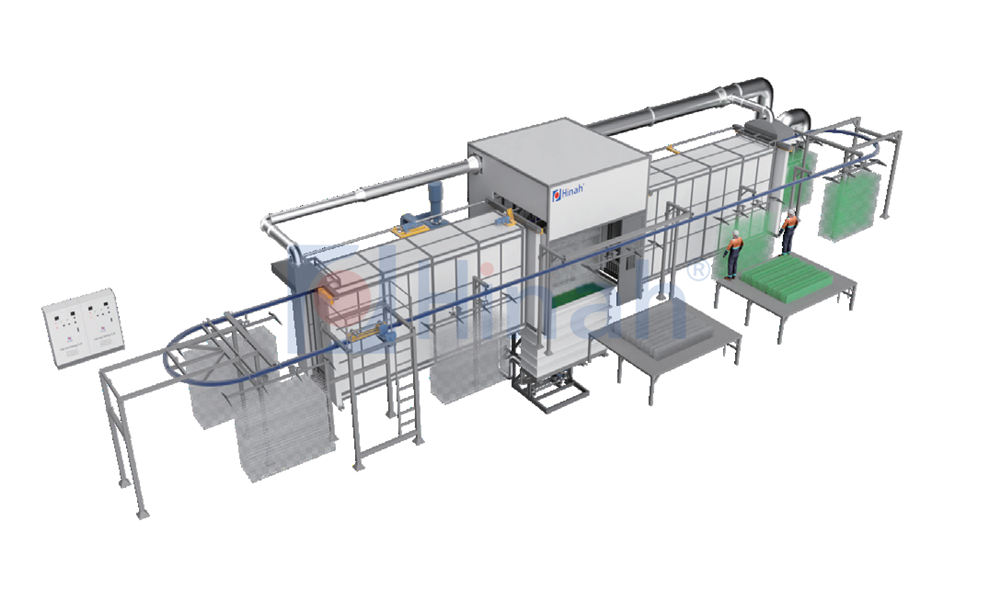

Deconstructing a Complete Finishing Line: Powder Coating Systems

A fully integrated powder coating systems is more than just an oven and a spray booth. It's a synchronized set of components working in harmony:

Pre-treatment Stage: Washers or chemical baths that clean, degrease, and phosphate the metal to ensure optimal adhesion.

Application Stage: The powder spray booth, recovery system, and guns where the powder is electrostatically applied.

Curing Stage: The industrial oven, which is the domain of powder coating oven manufacturers.

Material Handling: Conveyors that seamlessly move parts through each stage.

The oven is the most energy-intensive component of these powder coating systems. Its design directly impacts production throughput, energy consumption, and final product quality. Therefore, choosing a manufacturer who understands the integration of the oven within the entire system is crucial.

Powder coating oven manufacturers specialize in the design, engineering, fabrication, and sometimes installation of industrial curing ovens. Their expertise goes beyond simple heating elements. They must consider:

Heat Source: Whether electric, natural gas, infrared (IR), or liquid propane, each has advantages in cost, efficiency, and application.

Airflow and Design: Creating turbulent, uniform air movement to eliminate cold spots and ensure even curing on complex parts.

Insulation: High-quality insulation is vital for energy efficiency and maintaining a safe external temperature.

Control Systems: Advanced digital controls are necessary for precise temperature profiling and repeatability.

Configuration: Manufacturers build ovens in various configurations like batch (cabinet) ovens for low-volume work and conveyorized ovens for continuous production lines.

The best powder coating oven manufacturers act as partners, helping you determine the right specifications—size, heating technology, airflow pattern—based on your specific parts, production volume, and available facility space.

The Local Advantage: Finding Powder Coating Oven Manufacturers Near Me

The digital age makes it easy to search for global suppliers, but there is a significant advantage to searching for "powder coating oven manufacturers near me." A local manufacturer provides tangible benefits:

Easier Communication: Face-to-face meetings can streamline the planning and design process, reducing misunderstandings.

Lower Shipping Costs: Ovens are large, heavy, and expensive to ship. A local source can drastically reduce freight expenses.

Faster Service and Support: If an issue arises, having a local manufacturer means quicker response times for troubleshooting, maintenance, and obtaining replacement parts.

Understanding Local Regulations: A local manufacturer will be well-versed in your area's specific safety and environmental codes.

While a global search might yield more options, starting with "powder coating oven manufacturers near me" can lead to a more responsive and cost-effective partnership, especially for small to medium-sized enterprises.

Common Challenges and Problems in Powder Coating

Even with the best equipment, issues can arise. Understanding these common problems helps in selecting an oven that can prevent them.

Orange Peel: A textured finish resembling orange skin. This is often caused by improper film thickness or incorrect curing temperature/time. An oven with poor temperature uniformity can be a direct culprit.

Incomplete Curing: The powder doesn't fully melt and flow, leading to a soft, gummy finish that lacks durability. This is almost always a direct result of the oven temperature being too low or the cure time being too short. Inconsistent airflow within an oven can also cause certain areas of a part to be under-cured.

Over-Curing: Excessive heat or time can cause discoloration (yellowing of clear coats or whitening of certain pigments), brittleness, and a loss of mechanical properties.

Contamination: Dirt, oil, or other pollutants on the part before painting will cause fisheyes or craters. While primarily a pre-treatment issue, a poorly sealed oven can also introduce contaminants during the cure cycle.

Poor Adhesion: The coating chips or peels off easily. This can be due to inadequate pre-treatment but can also be worsened by an under-cured film.

High Energy Costs: Inefficient ovens are a massive drain on profitability. Poor insulation, outdated burner technology, and lack of energy recovery systems can lead to skyrocketing utility bills.

Many of these problems underscore why the choice of powder coating oven manufacturers is so critical. A well-designed oven provides the consistent, controllable, and efficient heat needed to avoid these costly defects.

Choosing the Right Partner Among Powder Coating Oven Manufacturers

Selecting a manufacturer is a significant decision. Here are key factors to consider:

Experience and Reputation: Look for established powder coating oven manufacturers with a proven track record and strong customer testimonials.

Customization Capability: Avoid one-size-fits-all solutions. Your manufacturer should be willing to design an oven that fits your unique requirements.

Energy Efficiency: Inquire about insulation values, heating technology, and any available energy-saving features. This will impact your operating costs for years to come.

Control and Automation: Modern digital controls with data logging capabilities are essential for quality control and repeatability.

Service and Support: Understand their warranty, availability of spare parts, and technical support services. This is where a local manufacturer often shines.

The Future is Efficient and Connected

The field of powder coating manufacturing is continuously evolving. Leading powder coating oven manufacturers are now integrating IoT (Internet of Things) capabilities for predictive maintenance and real-time performance monitoring. There is also a strong push towards more sustainable solutions, including ultra-high-efficiency burners, advanced IR technology for faster curing times, and heat recovery systems that reclaim energy from the oven exhaust.

The journey to a flawless, durable finish begins long before the powder is sprayed. It starts with a strategic investment in the right equipment from reputable powder coating oven manufacturers. Whether you are setting up a new line or retrofitting an existing one, prioritizing a high-quality, well-designed curing oven is non-negotiable. It is the engine of your finishing process, determining not only the quality of your product but also the efficiency and profitability of your entire powder coating manufacturing operation. By carefully evaluating your needs and partnering with a knowledgeable manufacturer, you can ensure your cure is perfect, every time.