Selecting the right industrial equipment is a critical decision that impacts your production quality, efficiency, and bottom line. When it comes to establishing or upgrading a powder coating line, the choice of powder coating oven manufacturers is paramount. This decision goes beyond simple price comparison; it involves assessing technology, durability, safety, and long-term partnership potential. A reliable manufacturer doesn't just sell a piece of equipment—they provide a solution tailored to your specific curing needs, ensuring consistent finishes and optimal throughput. In a market with numerous options, knowing what distinguishes the leading powder coating oven manufacturers can save significant time, cost, and operational headaches.

Why the Manufacturer Matters in Powder Coating

The performance of your powder coating process heavily relies on the curing stage. An oven must deliver precise, uniform heat distribution to ensure proper film flow, adhesion, and durability of the coating. Inconsistent temperatures can lead to defects like under-curing or over-curing, resulting in rework, wasted materials, and dissatisfied customers. Therefore, the expertise and reliability of your chosen powder coating oven manufacturers are directly linked to your product quality and operational success. Partnering with a seasoned manufacturer means investing in engineering precision, robust construction, and systems designed for real-world industrial demands.

Engineering and Build Quality: The Foundation of Performance

Superior engineering is non-negotiable. Top-tier powder coating oven manufacturers prioritize heavy-duty construction using quality materials like insulated panels with high R-values. This ensures excellent thermal efficiency, reducing heat loss and energy consumption. Look for features like uniform airflow design, efficient burner systems, and precise temperature controls. Companies like HANNA, for instance, focus on engineered solutions where every component, from the heating source to the control cabinet, is selected for durability and performance. A well-built oven maintains consistent temperatures across the entire workspace, which is essential for curing complex parts or full racks evenly.

Customization and Application-Specific Design

Off-the-shelf solutions rarely fit all. Your production line has unique requirements based on part size, geometry, throughput, and powder type. Leading powder coating oven manufacturers offer significant customization. This can include specific internal dimensions, specialized racking or conveyor integration (e.g., monorail, belt, or batch ovens), and tailored heat profiles. Whether you need a large walk-in oven for agricultural equipment or a compact batch oven for automotive components, the manufacturer should adapt the design to your process, not the other way around.

Energy Efficiency and Operational Cost Savings

With rising energy costs, an oven’s efficiency is a major financial consideration. Advanced powder coating oven manufacturers integrate technologies to minimize operating expenses. This includes high-efficiency burners, heat recovery systems, and superior insulation. Modern control systems allow for precise profiling and reduced idle heat. Investing in an energy-efficient model from a responsible manufacturer often has a faster return on investment through lower utility bills, making it a smart long-term economic decision.

Safety Features and Compliance Standards

Industrial ovens operate at high temperatures, making safety a top priority. Reputable powder coating oven manufacturers design and build equipment adhering to strict international safety standards (like NFPA, OSHA, or CE). Key safety features include comprehensive over-temperature protection, properly interlocked access doors, flame supervision systems for gas-fired units, and emergency shutdown procedures. A manufacturer’s commitment to safety protects your personnel, facility, and ensures regulatory compliance.

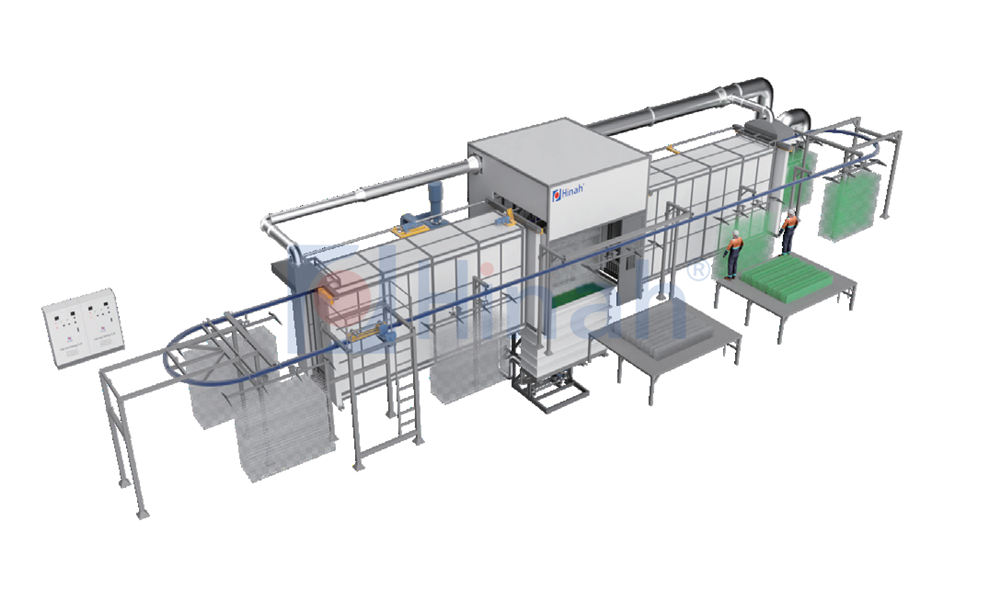

Integration with the Complete Powder Coating Line

An oven is one component of a larger system. The best powder coating oven manufacturers understand the entire process—from pretreatment and application to curing. They can advise on or provide solutions for seamless integration with washers, booths, and conveyors. This systems approach ensures smooth material flow, avoids bottlenecks, and optimizes the entire line’s performance. Manufacturers with this holistic view help create a more coherent and efficient production cell.

Technical Support and After-Sales Service

The relationship with your manufacturer doesn’t end at installation. Reliable technical support, availability of spare parts, and responsive service are crucial for minimizing downtime. Evaluate powder coating oven manufacturers on their service network, warranty terms, and reputation for support. Can they provide timely assistance for troubleshooting? Do they offer comprehensive operation and maintenance training? A strong service backbone is indicative of a company that stands behind its products for the long haul.

The HANNA Approach to Powder Curing Solutions

As an established player among global powder coating oven manufacturers, HANNA exemplifies the integration of these key factors. Their focus on robust, custom-engineered ovens addresses the core needs of durability and precise temperature control. HANNA’s designs emphasize energy-saving technologies and strict safety protocols, providing clients with efficient and secure operations. Their capability to design ovens as part of a fully integrated coating line highlights a comprehensive understanding of the finishing process. This customer-centric approach, backed by technical support, underscores what to look for in a manufacturing partner.

Making an Informed Decision for Your Investment

Choosing among powder coating oven manufacturers requires careful due diligence. Consider not only the initial quote but also the total cost of ownership, including energy use, maintenance, and potential production losses from poor performance. Request detailed specifications, visit manufacturing facilities if possible, and ask for client references. A partner like HANNA demonstrates that the right manufacturer invests in engineering excellence and customer success, providing a solution that enhances your finishing quality and productivity for years to come.

Ultimately, your selection of powder coating oven manufacturers will define the reliability and quality of your curing process. Prioritize build quality, customization, efficiency, and strong service to ensure your investment drives value and supports your business growth in the competitive field of industrial finishing.

Frequently Asked Questions (FAQs)

Q1: What is the most important factor when choosing between powder coating oven manufacturers?

A1: While price is a consideration, the most critical factor is build quality and engineering design. An oven must provide precise, uniform heat distribution for consistent curing. Prioritize manufacturers known for robust construction, efficient insulation, and advanced control systems, as these elements directly impact finish quality and long-term operational costs.

Q2: Can powder coating oven manufacturers customize ovens for unusual part sizes?

A2: Yes, leading manufacturers specialize in customization. They can design ovens with specific internal dimensions, door configurations, and heat zones to accommodate very large, small, or irregularly shaped parts. It’s essential to provide detailed part specifications and throughput requirements during the consultation phase.

Q3: How do energy-efficient ovens from top manufacturers reduce operating costs?

A3: Energy-efficient ovens incorporate high-performance insulation, heat recovery systems, and high-efficiency burners or heating elements. These features significantly reduce the energy required to reach and maintain curing temperatures, leading to substantially lower monthly utility bills and a better return on investment.

Q4: What safety certifications should I look for from powder coating oven manufacturers?

A4: Look for manufacturers whose ovens comply with recognized international safety standards. Key certifications or design adherence include NFPA (National Fire Protection Association) standards, OSHA (Occupational Safety and Health Administration) guidelines, and the CE mark for equipment sold in the European Union, indicating safety, health, and environmental protection.

Q5: What kind of after-sales support should I expect from a reputable manufacturer?

A5: Comprehensive support includes detailed installation guidance, operator training, readily available spare parts, and responsive technical service for troubleshooting. A strong manufacturer will offer a clear warranty and have a knowledgeable service team to help minimize downtime, ensuring your production line remains operational.