In the world of industrial finishing, a paint curing oven is not just an accessory—it’s the heart of the process. Whether you’re working with powder coating, liquid paint, or advanced composites, the right curing system defines product quality, durability, and throughput.

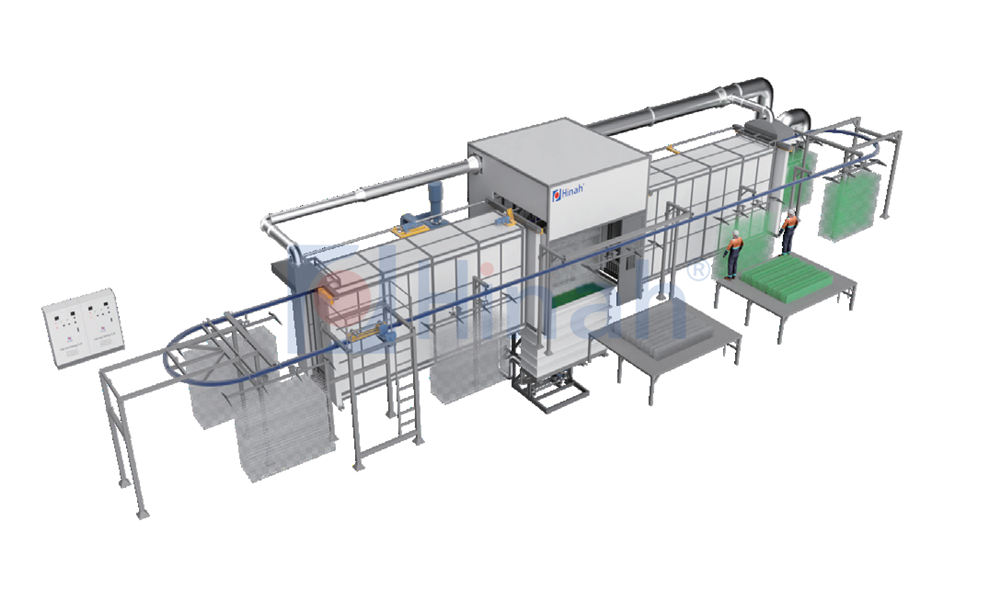

This guide explores everything you need to know about modern paint curing ovens, including types, technologies, and how custom solutions from brands like HANNA can transform your production line.

What Is a Paint Curing Oven and How Does It Work?

A paint curing oven is a thermally insulated chamber used to harden applied coatings through controlled heating. The process involves cross-linking polymers in the paint or powder, creating a durable, uniform finish.

The science is straightforward but precise. After a part is coated, it enters the paint curing oven. Heat triggers a chemical reaction. For powder coatings, this is called “cross-linking.” The result is a tough, smooth layer resistant to chips, scratches, and corrosion.

Temperature uniformity is critical. Even heat distribution ensures consistent curing. Even a small cold spot can lead to under-cured areas. This affects adhesion and longevity. Modern ovens use advanced airflow designs and control systems to prevent this.

Key Types of Paint Curing Ovens in Industrial Use

Not all paint curing ovens are the same. The choice depends on production volume, part size, coating type, and energy goals. Here are the most common types used in powder coating and industrial finishing.

Convection Curing Ovens

These are the most widely used. Heated air is circulated around parts using fans. This ensures even temperature distribution. Convection ovens are versatile. They work well for odd-shaped parts and batch processing. HANNA convection ovens are known for their efficient airflow designs.

Infrared (IR) Curing Ovens

IR ovens use electromagnetic radiation to directly heat the coating and substrate. They cure surfaces quickly. This makes them ideal for conveyorized lines. Energy efficiency is high because they heat the product, not the air. However, shadowed areas may not cure evenly.

Combination Hybrid Ovens

Many modern systems combine convection and infrared technologies. This hybrid approach offers speed and uniformity. It’s perfect for complex part geometries. A custom paint curing oven from HANNA can be engineered to balance both methods.

Batch Ovens vs. Conveyor Ovens

Batch ovens are great for low-volume or large, heavy parts. Conveyor ovens provide continuous curing for high-volume production. The choice impacts your entire workflow.

The Critical Role of Temperature Control and Uniformity

Precise temperature control separates adequate ovens from exceptional ones. In powder coating, typical cure temperatures range from 150°C to 210°C (300°F to 410°F). The exact requirement depends on the powder formula.

A high-quality paint curing oven maintains temperature within a tight tolerance, often ±5°C or better. This is achieved with multi-zone control systems. Each zone can be adjusted independently. This compensates for heat loss near doors or loading areas.

Uniformity is equally important. Sophisticated airflow patterns ensure every part receives the same thermal treatment. HANNA engineers use Computational Fluid Dynamics (CFD) to model air movement. This guarantees no weak spots in the cure.

Energy Efficiency: Reducing Costs and Environmental Impact

Operating a paint curing oven is energy-intensive. That’s why efficiency is a major focus. Modern designs incorporate several energy-saving features.

Insulation is the first defense. High-density mineral wool or ceramic fiber reduces heat loss. This keeps energy inside the chamber. Heat recovery systems are another advance. Exhaust air is used to preheat incoming fresh air. This significantly reduces fuel or electricity consumption.

Indirect-fired heating options improve air quality. They prevent combustion byproducts from entering the curing chamber. This is crucial for sensitive finishes. HANNA’s custom paint curing ovens often include tailored energy recovery solutions. This cuts operating costs and supports sustainability goals.

Custom Paint Curing Ovens: Tailoring the Solution to Your Line

“One-size-fits-all” rarely works in industrial finishing. That’s where custom paint curing oven solutions become essential. A tailored oven matches your exact production needs.

Consider part size and geometry. Large agricultural equipment needs a very different oven than electronic enclosures. Throughput rate determines oven size and heating capacity. A custom paint curing oven from HANNA is designed around your specific parts and cycle times.

Integration with existing conveyors, washers, and coolers is also critical. A well-engineered oven fits seamlessly into your line. This minimizes downtime during installation. HANNA specialists work with you from concept to commissioning.

Why HANNA Paint Curing Ovens Stand Out in Powder Coating

HANNA has built a reputation for reliability and innovation. Their paint curing ovens are known for robust construction and intelligent design.

Durability comes from premium materials. High-grade steel framing and long-life heating elements ensure years of service. Smart control systems are user-friendly. They allow operators to monitor and adjust curing profiles easily.

HANNA’s support extends beyond installation. They provide comprehensive maintenance guidance and technical support. This ensures your paint curing oven operates at peak performance for its entire lifecycle.

Future Trends: Smarter and More Sustainable Curing

The future of paint curing oven technology points toward greater automation and sustainability. Industry 4.0 integration is becoming standard. Ovens now feature IoT sensors and connectivity.

Real-time data monitoring allows predictive maintenance. This prevents unexpected downtime. Advanced controls can automatically adjust parameters for different products. This improves quality and reduces waste.

Low-temperature cure powders are gaining popularity. They require less energy to cure. Paint curing ovens are adapting to these new materials. HANNA is at the forefront of these developments, designing ovens ready for tomorrow’s coatings.

Frequently Asked Questions (FAQs) About Paint Curing Ovens

Q1: What is the typical temperature range for a powder coating paint curing oven?

A1: Most powder coatings cure effectively between 150°C and 210°C (300°F to 410°F). The exact temperature and time depend on the specific powder manufacturer's recommendations. A well-designed paint curing oven provides precise control within this range to ensure perfect results every time.

Q2: How can I improve the energy efficiency of my existing paint curing oven?

A2: Several upgrades can boost efficiency. Start by inspecting and improving door seals and insulation to minimize heat loss. Consider adding a heat recovery system to capture waste energy. Also, optimizing cure cycles and performing regular maintenance on burners and airflow systems can lead to significant savings. HANNA offers retrofit services to modernize older ovens.

Q3: What are the main advantages of a custom paint curing oven over a standard model?

A3: A custom paint curing oven is engineered for your specific parts, production volume, and facility layout. This leads to optimal cure uniformity, faster cycle times, seamless integration with your line, and ultimately, lower operating costs per part. It eliminates the compromises often required with off-the-shelf solutions.

Q4: How important is airflow design inside a paint curing oven?

A4: Airflow design is absolutely critical. It directly impacts temperature uniformity, which dictates coating quality. Poor airflow creates hot and cold spots, leading to under-cured or over-cured areas. HANNA ovens use advanced engineering, including CFD modeling, to create optimized airflow patterns that ensure consistent results across the entire load.

Q5: What maintenance does a paint curing oven require to ensure longevity?

A5: Regular maintenance is key. Daily or weekly tasks include checking and cleaning air filters and ensuring door seals are intact. Monthly, inspect burners, ignition systems, and fans. Annually, a comprehensive inspection of insulation, heating elements, and control system calibration is recommended. Following HANNA’s tailored maintenance schedule will maximize your oven's service life and performance.