If your production involves farm equipment, construction machinery, architectural aluminum, or heavy-duty industrial components, you understand the challenge. Standard finishing ovens simply won't fit. You need a powerhouse built for scale and durability. You need a Large Powder Coating Oven.

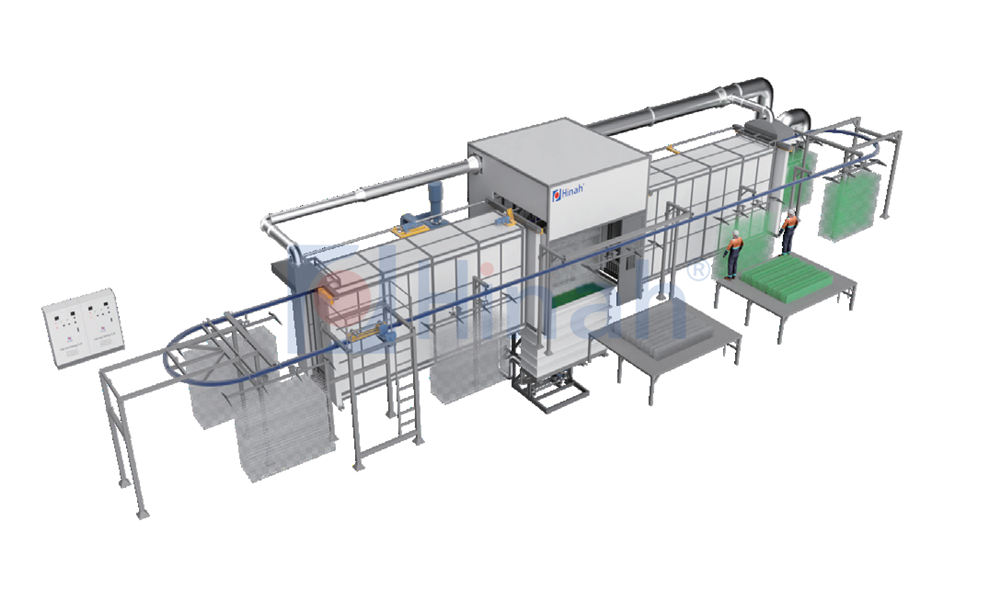

This isn't just about bigger dimensions. It's about engineered performance for massive throughput and uncompromising finish quality. This guide dives deep into the world of large powder coating ovens, exploring their critical design considerations, operational benefits, and why a custom approach from a specialist like HANNA is often the only viable path to success.

What Defines a Large Powder Coating Oven?

In industrial coating, "large" is a functional term, not just a physical one. A large powder coating oven is specifically engineered to cure oversized, heavy, or high-volume products that cannot be processed in standard commercial units.

Think of walk-in room ovens big enough for a tractor cabin. Imagine continuous conveyor ovens stretching over 50 meters for aluminum extrusions. These systems handle parts measuring several meters in any dimension and weights measured in tons.

The core function remains the same: to provide the precise, uniform heat required to melt and cure thermoset powder coatings into a resilient finish. The engineering, however, is on a completely different scale.

Key Applications Demanding Large-Scale Curing

The need for a large powder coating oven spans industries where product size and environmental resistance are paramount.

Agriculture & Construction: Combines, plows, excavator arms, and bulldozer blades. These parts face extreme abrasion and corrosion.

Architectural & Building Products: Curtain walls, window frames, and structural steel for bridges. They require decades of weather and UV resistance.

Transportation: Truck trailers, bus frames, and rail components. Durability and aesthetics are critical.

Heavy Machinery & Industrial Equipment: Generators, storage tanks, and manufacturing frames. The finish must protect against harsh factory environments.

For these applications, a powder-coated finish applied and cured correctly in a reliable large industrial oven is a key competitive advantage.

Why Off-the-Shelf Rarely Works: The Case for Custom Design

You cannot simply scale up a small oven's design. The physics change. This is why a custom large powder coating oven is not a luxury—it's a necessity for efficiency and quality.

Every project starts with key parameters: maximum part dimensions, weight, production rate (lbs/hour or parts/hour), and the specific powder's cure schedule. A HANNA custom powder coating oven is then designed from the ground up around your product and workflow.

Whether it's an overhead monorail system, an inverted conveyor for extrusions, or a floor-standing rack process, the oven is integrated seamlessly. This tailored approach eliminates bottlenecks, minimizes energy waste, and ensures every square inch of your largest part reaches the perfect cure temperature.

Critical Engineering Challenges & How HANNA Solves Them

Designing an effective large powder coating oven involves overcoming significant engineering hurdles.

Temperature Uniformity is King. In a vast chamber, maintaining ±5°C (or better) from top to bottom and side to side is the greatest challenge. Cold spots lead to under-cure; hot spots can degrade the substrate. HANNA utilizes advanced, multi-zone airflow technology. Strategically placed fans and tuned plenums create a consistent, turbulent air blanket that envelops even the most complex geometries.

Structural Integrity & Safety. The framework must support massive weights and withstand constant thermal expansion and contraction. HANNA builds with heavy-duty structural steel and high-grade insulation. Safety systems, including pressure relief vents and comprehensive combustion safeguards (for gas-fired models), are integral, not optional.

Energy Efficiency at Scale. The energy cost of heating a warehouse-sized space can be staggering. Modern large powder coating ovens combat this with superior insulation (often R-values far exceeding standard), high-efficiency burners, and sophisticated heat recovery systems. Capturing exhaust heat to pre-heat incoming air can slash fuel consumption by 30% or more, a direct benefit of HANNA's engineered solutions.

Operational Accessibility. How do you load 5-ton parts? Design must include appropriately sized doors (vertical lift, horizontal slide, or roll-up), robust internal rail systems, and often, specialized material handling integration. The oven design works in concert with your plant's logistics.

Gas vs. Electric Heating: Choosing the Right Power Source

The choice between gas and electric heating for your large powder coating oven has major implications for cost and performance.

Direct-Fire or Indirect-Fire Gas Systems are common for large-scale operations, especially in North America. They offer rapid heat ramp-up and lower operating costs where natural gas is affordable. Indirect-fired systems are preferred for powder, as they prevent combustion byproducts from contaminating the finish.

Electric Infrared (IR) or Convection Systems provide clean, precise heat. Electric IR is excellent for conveyorized lines with uniform part profiles, heating the part directly. Electric convection offers excellent control. The choice often depends on local utility rates and environmental regulations.

HANNA's engineers help you analyze your specific throughput, part mix, and local costs to determine the most economical and effective heating strategy for your custom industrial oven.

The HANNA Advantage in Large-Scale Finishing Systems

Choosing a partner for your large powder coating oven is a long-term decision. HANNA brings decades of focused expertise to the table.

We don't just sell an oven; we deliver a complete powder coating system solution. Our process begins with a deep analysis of your needs. We then design, fabricate, install, and commission a system that functions as a reliable production asset.

Our builds are known for durability, using commercial-grade components throughout. Our intuitive control systems, often featuring touchscreen HMIs and data logging, empower your operators. Most importantly, our support continues long after installation, with readily available service and technical guidance.

Investing in a HANNA large powder coating oven means investing in consistent finish quality, reduced rework, lower per-part energy costs, and a system built to last for decades of heavy industrial use.

Frequently Asked Questions (FAQs)

Q1: What are the typical temperature and time requirements for curing in a large powder coating oven?

A1: Most standard powder coatings cure between 180°C to 200°C (356°F to 392°F) for 10-15 minutes at the part's metal temperature. However, for large, thick metal parts, the "come-up time"—the time it takes for the entire mass to reach temperature—must be accounted for. Total cycle time may be longer. Always follow the powder manufacturer's Technical Data Sheet (TDS) for the exact cure profile.

Q2: How is energy consumption managed in such a large industrial oven to keep costs under control?

A2: Managing energy in a large powder coating oven relies on design. Key features include high-density insulation (minimizing heat loss), multi-zone temperature control (heating only what's needed), high-efficiency burners or heaters, and most effectively, heat recovery systems. These systems capture thermal energy from the exhaust air and use it to pre-heat incoming fresh air, dramatically reducing fuel or power demand.

Q3: Can a large oven handle different types of powders or products with varying cure schedules?

A3: Yes, with proper design. A modern custom large powder coating oven from HANNA features programmable logic controllers (PLCs) with multiple recipe storage. An operator can select a recipe for a specific product, and the oven will automatically adjust zone temperatures and conveyor speed (if applicable) to meet the new cure schedule, providing excellent operational flexibility.

Q4: What kind of maintenance is required for a large industrial curing oven?

A4: Regular preventative maintenance is crucial for longevity and efficiency. Daily/Weekly: Check and clean air intake filters. Monthly: Inspect fan motors, bearings, and door seals. Annually: A full inspection by a qualified technician is recommended, including calibration of temperature sensors, checking burner/ignition systems (for gas ovens), and verifying airflow balance. HANNA provides detailed maintenance manuals and support.

Q5: How do you ensure even heat distribution around very large, dense parts?

A5: This is the core of our design expertise. We use Computational Fluid Dynamics (CFD) software to model airflow and heat transfer within the custom oven chamber before it's built. This allows us to engineer the fan placement, baffle configuration, and ductwork to create a uniform "air blanket." For extremely dense parts, we may design specific zoning or adjust airflow patterns to ensure heat penetrates effectively to the core of the part.