Achieving a flawless finish is the goal of every coater. However, environmental factors often stand in the way. Dust, humidity, and temperature fluctuations can ruin a perfectly sprayed part. This is why dedicated powder coating rooms are becoming a standard requirement for high-quality production lines.

A simple spray booth is often not enough. The booth captures the overspray, but it does not control the environment surrounding the operator and the parts. Powder coating rooms serve as the first line of defense against contamination. They create a "clean room" atmosphere that isolates the finishing process from the dirty reality of the factory floor.

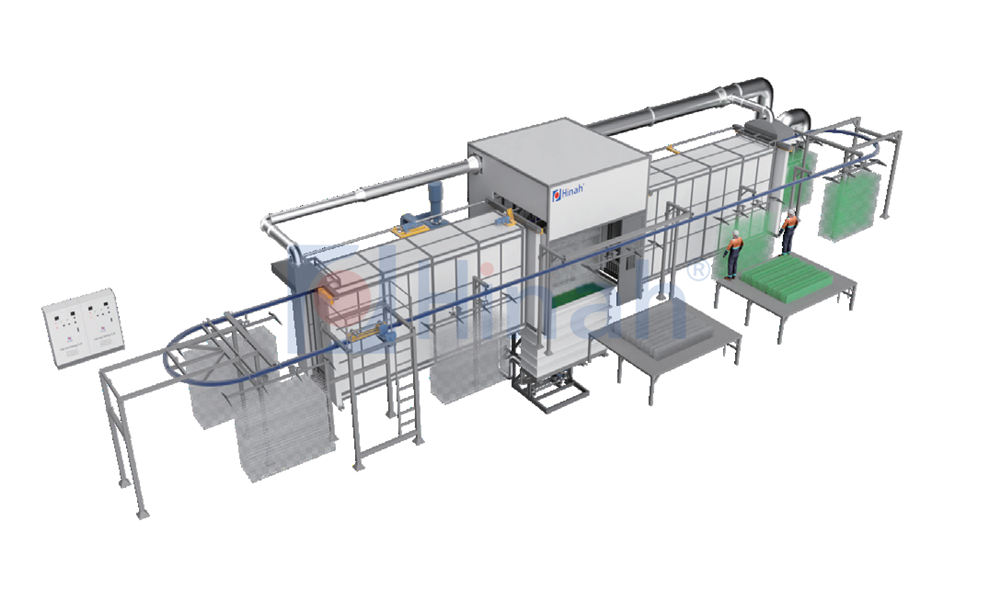

For businesses looking to reduce rejection rates, investing in engineered powder coating rooms is a strategic move. It transforms a general workshop into a professional finishing facility. Companies like HANNA have recognized this need, designing enclosures that ensure stability and cleanliness for the coating process.

The Function of Powder Coating Rooms in Production

The primary function of powder coating rooms is contamination control. In a typical factory, forklifts kick up dust. Grinding operations create metal shavings. If these particles land on a part before it enters the oven, they create defects.

Powder coating rooms act as a barrier. By enclosing the spray booth and the staging area, you physically block airborne debris. This is crucial for industries like automotive or aerospace, where visual perfection is mandatory.

Beyond dust, these rooms manage airflow. A spray booth pulls air in. If the surrounding air is turbulent or dirty, the booth’s filters clog faster. Powder coating rooms provide a calm, controlled supply of air, allowing the booth to operate at peak efficiency.

Importance of Positive Pressure

The most effective powder coating rooms operate under positive pressure. This is a critical engineering concept. Positive pressure means the air pressure inside the room is slightly higher than the air pressure outside in the main factory.

When you open a door to a positive pressure room, air rushes out. It does not rush in. This prevents dust and dirt from entering the room when operators enter or exit. HANNA engineers their systems to maintain this delicate pressure balance.

To achieve this, powder coating rooms require an Air Make-Up Unit (AMU). The AMU pumps filtered air into the room. This air is cleaner than the general shop air. It pushes contaminants away from the critical spraying zone.

Temperature and Humidity Control

Powder coating is a chemical process. The powder material is sensitive to heat and moisture. High humidity can cause the powder to clump. It leads to poor flow and "orange peel" textures on the finished product.

Advanced powder coating rooms include HVAC integration. Controlling the temperature keeps the powder fluid. Controlling humidity prevents clumping and electrical grounding issues.

If the air is too dry, static electricity becomes unmanageable. The powder won't stick to the part effectively. Powder coating rooms that maintain a humidity level of roughly 40-60% typically see the best transfer efficiency. HANNA often advises clients on specific environmental parameters based on their geographic location.

Wall Construction and Materials

The walls of powder coating rooms must be smooth and easy to clean. Rough surfaces trap dust. Over time, this dust builds up and falls onto fresh wet parts.

Most manufacturers use insulated sandwich panels. These panels consist of two metal sheets with an insulating core. They provide thermal insulation and structural rigidity. They are also easy to wipe down.

HANNA utilizes high-quality panels that are anti-static. This prevents powder dust from clinging to the walls of the powder coating rooms. A quick wipe-down at the end of a shift restores the room to a pristine condition, ready for the next color change.

Lighting Requirements in Powder Coating Rooms

You cannot fix what you cannot see. Lighting is one of the most undervalued aspects of powder coating rooms. Standard warehouse lighting is rarely sufficient for detailed inspection and application.

The room requires high-lux, shadow-free illumination. LED lights are the industry standard. They must be positioned to light the part from all angles. This helps the coater see into corners and deep recesses.

Furthermore, the lighting in powder coating rooms must be explosion-proof or sealed. Powder dust can be combustible. Electrical fixtures must be rated for hazardous environments to ensure the safety of the facility and the staff.

The Role of HANNA in Environmental Design

HANNA has established itself as a leader in providing complete finishing solutions. Their approach to powder coating rooms goes beyond simple walls. They view the room as part of the total ecosystem.

HANNA designs the room layout to optimize workflow. They consider where the parts enter, where the operator stands, and how the air moves. Their designs minimize turbulence, which is the enemy of efficient powder application.

By integrating the booth, the conveyor, and the enclosure, HANNA ensures that the powder coating rooms they build add value. They focus on energy efficiency, ensuring that the air handling systems do not consume unnecessary power.

Reducing Rejection Rates

The cost of a rejected part is high. You lose the labor of hanging, washing, and spraying the part. You also lose the energy used to cure it. Then, you have to strip the part and start over.

Implementing powder coating rooms dramatically reduces these costs. When the environment is clean, the finish is consistent. Defects caused by trash in the paint drop significantly.

Many shop owners find that the ROI on powder coating rooms is fast. By saving just a small percentage of parts from rework, the enclosure pays for itself. It also improves customer satisfaction by delivering a reliable product every time.

Safety and Compliance

Industrial finishing is a regulated industry. Powder coating rooms help businesses comply with safety standards. By containing the process, you limit the spread of combustible dust.

Regulatory bodies often require separation between spraying operations and other manufacturing processes like welding. A fire-rated enclosure satisfies these requirements.

HANNA ensures that their powder coating rooms meet international safety standards. This includes proper emergency exits, viewing windows, and fire suppression integration where necessary. Safety is not an option; it is a necessity in modern manufacturing.

Integrating Conveyor Systems

Most industrial powder coating rooms are designed around a conveyor system. The parts enter through a silhouette opening. This opening must be sealed as much as possible to maintain pressure.

Air knives or brushes are often used at the conveyor entry and exit points. These devices keep the internal air in and the external dust out.

HANNA specializes in these integrations. They ensure that the conveyor track moves smoothly through the room without creating gaps in the enclosure. This attention to detail preserves the integrity of the clean environment.

Manual vs. Automated Operations

Powder coating rooms are beneficial for both manual and automated lines. For manual coaters, the room provides a comfortable, well-lit workspace. It reduces fatigue and improves focus.

For automated lines, the room protects the reciprocators and guns. Automated systems are precise. Dust on a sensor can cause a machine fault. A clean room keeps the automation running without interruption.

Regardless of the application method, the principle remains the same: control the variables. Powder coating rooms control the variables of air, heat, and dirt.

Maintenance of the Enclosure

Building the room is step one. Maintaining it is step two. Powder coating rooms require a cleaning schedule. If the floor is dirty, the positive pressure will just blow that dust around.

Operators should wear lint-free suits and shoe covers. Tacky mats should be placed at the entrance to pull dirt off shoes.

The walls and light fixtures should be wiped down regularly. HANNA designs their rooms with smooth transitions between walls and floors to eliminate "dust traps" where dirt can hide. This makes maintenance quick and effective.

Energy Efficiency Considerations

Conditioning air costs money. Heating or cooling the air pumped into powder coating rooms increases utility bills. Therefore, the design must be efficient.

Recirculation systems can help, provided the air is heavily filtered. However, for safety, a certain amount of fresh air is always required.

Insulation plays a big role here. The insulated panels used by HANNA keep the conditioned air inside. This reduces the load on the HVAC system. Smart controls can also lower the airflow when the spray gun is not in use, saving energy during downtime.

Troubleshooting Common Room Issues

If you have powder coating rooms but still see defects, check the pressure. A simple gauge can tell you if the room is still under positive pressure. If not, check the door seals and filter banks.

Another common issue is lighting degradation. As lights get old or dirty, it is harder to see light patches on the parts. Regular light meter checks can prevent this.

Finally, check for air leaks. A gap in the conveyor slot can let in a stream of dirty air. Regular audits of the enclosure ensure that the powder coating rooms continue to perform as designed.

The difference between a backyard shop and a professional finisher is often the environment. Powder coating rooms provide the clean, stable conditions necessary for high-end manufacturing. They protect the product, the equipment, and the employees.

Investing in a proper enclosure reduces rework and increases profitability. It allows you to control the quality of the air, which directly controls the quality of the finish.

Manufacturers like HANNA are essential partners in this process. They bring the engineering knowledge required to build powder coating rooms that work efficiently. By prioritizing the environment, you prioritize quality.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a spray booth and powder coating rooms?

A1: A spray booth is the specific equipment that captures the overspray and filters the air during the application. Powder coating rooms are the larger, enclosed environments (rooms) that house the booth, the operator, and the parts. The room controls the ambient temperature, humidity, and cleanliness, protecting the entire process from the rest of the factory.

Q2: Do I need an air make-up unit (AMU) for my room?

A2: Yes, an AMU is highly recommended for professional powder coating rooms. The spray booth exhausts a large volume of air. Without an AMU replacing that air, the room will have negative pressure, sucking in dust from the factory. An AMU provides filtered, conditioned air to create positive pressure and keep contaminants out.

Q3: What is the ideal humidity level for powder coating rooms?

A3: The industry standard is typically between 40% and 60% relative humidity. If the air is too humid (above 60%), powder can clump and flow poorly. If it is too dry (below 30-40%), static electricity becomes difficult to manage, making it hard for the powder to stick to the grounded part. HANNA can help design HVAC systems to maintain this balance.

Q4: Can HANNA retrofit a room around an existing conveyor line?

A4: Yes, HANNA specializes in custom configurations. They can design powder coating rooms that fit around existing equipment, including conveyors, ovens, and pretreatment tunnels. They use modular panel systems that allow for flexibility in installation and future expansion.

Q5: How often should the walls of powder coating rooms be cleaned?

A5: It depends on production volume, but a general rule is to squeegee or wipe down the walls during every color change to prevent cross-contamination. For general cleanliness, a thorough cleaning of the floors and walls should happen at least once a week. Keeping the powder coating rooms clean prevents old powder from becoming airborne and landing on new parts.