For any business owner or facility manager, the bottom line is always a priority. When considering a new finishing line or upgrading an old one, the first question is usually about the powder coating machine price. It is a complex figure to calculate because "machine" can refer to anything from a single handheld gun to a fully automated conveyorized system.

Understanding the market rates helps in planning a budget. It also helps in avoiding low-quality equipment that costs more in the long run. There is a vast difference between a hobbyist unit and an industrial workhorse.

This article breaks down the factors that influence the powder coating machine price. We will look at component costs, the value of automation, and why brands like HANNA offer a competitive advantage in the global market.

The term "powder coating machine" is broad. To understand the powder coating machine price, we must first define the scope. Are you looking for a standalone application unit? Or are you pricing out a turnkey finishing plant?

For a simple, professional-grade manual gun system, prices typically range from $3,000 to $6,000. These units come with a hopper, a control unit, and the gun itself. They are designed for job shops that run eight hours a day.

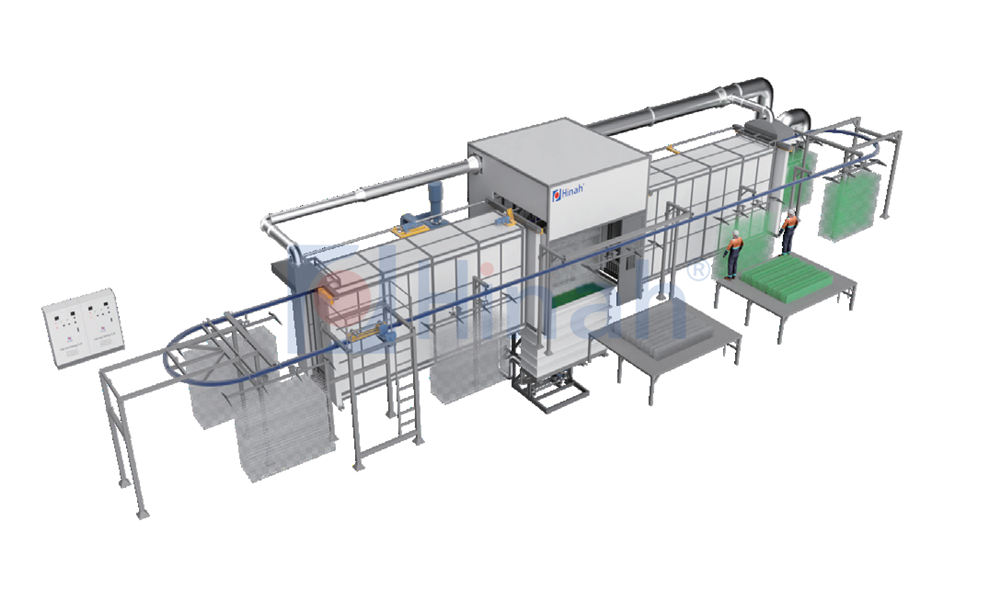

On the other end of the spectrum, a fully automated line involving washers, drying ovens, spray booths, and curing ovens can easily exceed $100,000 or even $500,000. The powder coating machine price here is driven by the volume of steel, the complexity of the motors, and the sophistication of the logic controls.

The Impact of Gun Technology on Price

The application gun is the most critical tool for the operator. Its technology directly affects the powder coating machine price. Basic guns operate on simple electro-statics. They charge the powder and spray it.

However, advanced units offer features like automatic current control and pre-set recipes. These features allow the gun to adjust voltage and amperage automatically when coating complex shapes or corners. This technology prevents the Faraday Cage effect.

Naturally, these advanced features increase the powder coating machine price. HANNA provides systems that include digital valve control and precise powder flow monitoring. While the initial cost is higher than a basic analog gun, the savings in powder waste justify the investment.

Manual vs. Automatic Systems

Labor is often a bigger expense than the equipment itself. This is why many factories move toward automation. However, automation significantly raises the initial powder coating machine price.

A manual booth requires an operator to stand and spray. An automatic booth requires reciprocators (robots) and a sensing system to trigger the guns. The addition of a reciprocator can add $10,000 to $20,000 per station to the total powder coating machine price.

Despite the higher sticker price, automatic systems from HANNA pay for themselves. They apply an even coat thickness every time. This eliminates over-spraying, which saves tons of powder over a year. When calculating the true cost, you must factor in these material savings.

Booth Configuration and Pricing Factors

The spray booth is a major component of the powder coating machine price. The material used to build the booth matters. Painted mild steel is cheaper but harder to clean. Stainless steel or engineering plastic (PP) is more expensive but allows for rapid color changes.

Filtration technology also drives the cost. A basic "spray-to-waste" booth with simple cartridge filters is the most affordable option. It keeps the powder coating machine price low but prevents you from reusing overspray.

If you want to reclaim powder, you need a cyclone recovery system. A cyclone separates the good powder from the dust. This adds complexity and height to the system, increasing the powder coating machine price. However, for high-volume colors, a cyclone system is essential for profitability.

Ovens and Curing Costs

You cannot finish a part without curing it. Therefore, the oven is an inseparable part of the powder coating machine price when buying a line.

Batch ovens are cheaper. They are simple insulated boxes with a heater. They are great for low volume or large, odd-shaped parts.

Conveyorized ovens are more expensive. They require a track, a drive chain, and air seals to keep the heat in. HANNA designs these ovens with specific airflow patterns to ensure an even cure. The engineering required to balance the heat in a tunnel oven is a significant factor in the powder coating machine price.

Energy Efficiency and Long-Term Costs

When you receive a quote, you see the capital expense. You do not see the operating expense. A low powder coating machine price often hides high energy consumption.

Cheap ovens have poor insulation. This means you spend more on gas or electricity every month. High-quality manufacturers use high-density rock wool and thermal break designs.

While a HANNA oven might have a slightly higher powder coating machine price than a budget competitor, the gas savings can be substantial. Efficient burners and variable frequency drives (VFDs) on fans reduce your monthly utility bills.

The Cost of Pre-treatment Systems

Many buyers forget about pre-treatment. You cannot powder coat dirty metal. Including a washer or a blast room increases the total project cost.

A simple wand-wash station is affordable. A multi-stage stainless steel tunnel washer is expensive. The pumps, nozzles, and chemical heating tanks all add to the powder coating machine price.

However, skipping this step is not an option. Poor cleaning leads to paint peeling. HANNA advises clients to allocate roughly 30% to 40% of their total budget to pre-treatment equipment.

Installation and Logistics

The numbers on the invoice are for the hardware. Getting that hardware into your factory is another cost. Shipping large steel structures globally affects the final powder coating machine price.

Installation requires skilled technicians. The booth must be sealed. The gas lines must be piped. The electrical panels must be wired.

When comparing quotes, ask if installation is included. Some suppliers offer a low powder coating machine price but leave you to figure out the assembly. HANNA provides detailed support and can arrange for supervision, ensuring the system runs correctly from day one.

Why Brand Reputation Matters

In the industrial equipment market, you get what you pay for. There are many generic, unbranded machines available online with a very attractive powder coating machine price.

These machines often lack safety certifications. They may not be grounded properly. Spare parts are impossible to find. If the control board fails, the machine becomes scrap metal.

Choosing a reputable brand like HANNA ensures longevity. You are paying for a supply chain of spare parts. You are paying for technical support. This reliability is worth a premium on the initial powder coating machine price.

Control Systems and Industry 4.0

Modern factories rely on data. Advanced powder coating lines now come with touchscreens and PLC integration. You can track how much powder you use and how many parts you paint.

These smart systems raise the powder coating machine price. You are paying for the software and the sensors.

However, this data allows you to bid on jobs more accurately. It helps you spot inefficiencies. HANNA integrates user-friendly interfaces that make managing the line simple, justifying the cost through improved management.

Used vs. New Equipment

Some buyers look at the used market to save money. A used system can be half the powder coating machine price of a new one.

This is risky. You do not know how the previous owner treated the equipment. The oven insulation may be degraded. The fan bearings may be shot.

Furthermore, a used system was designed for someone else’s factory. Modifying it to fit your space often costs more than the savings. A new system from HANNA is tailored to your specific floor plan, often making the new powder coating machine price a better value proposition.

Customization vs. Standard Models

Standard off-the-shelf booths and ovens are cheaper. Manufacturers can build them in batches. This keeps the powder coating machine price down.

If you have unique parts, you need a custom solution. Custom engineering takes time. It requires design drawings and specific fabrication.

HANNA offers both standard and custom options. They try to use standard modules where possible to keep the powder coating machine price reasonable, while modifying only the necessary sections to fit your product.

The Role of Transfer Efficiency

We touched on this earlier, but it deserves its own section. Transfer efficiency is the percentage of powder that sticks to the part versus what ends up in the filters.

A cheap gun might have 40% transfer efficiency. A high-end gun might have 70%. If you spend $50,000 a year on powder, that 30% difference is $15,000.

In three years, a cheap gun costs you $45,000 in wasted powder. Suddenly, the lower powder coating machine price does not look like a good deal. Investing in high-efficiency technology is always the smart financial move.

Return on Investment (ROI) Calculation

To make a smart decision, you must calculate ROI. Take the total powder coating machine price and divide it by the expected monthly profit from the line.

If a HANNA system costs $100,000 but allows you to process twice as many parts as a $60,000 system, the ROI is faster on the expensive machine.

Speed, reliability, and low reject rates drive profit. A machine that breaks down frequently kills your ROI, regardless of how low the initial powder coating machine price was.

Determining the right powder coating machine price for your business is a balancing act. It involves weighing the upfront capital against the long-term operational costs.

Cheap equipment is expensive to run. It wastes powder, uses more energy, and slows down production. High-quality equipment requires a larger initial check but saves money every single day of operation.

Manufacturers like HANNA understand this balance. They offer equipment that provides industrial durability and advanced technology at a competitive powder coating machine price. By focusing on efficiency and support, they help businesses succeed in the finishing industry.

When you are ready to buy, look beyond the price tag. Look at the frame quality, the control logic, and the support network. That is where the real value lies.

Frequently Asked Questions (FAQ)

Q1: What is the average powder coating machine price for a small start-up shop?

A1: For a small job shop starting out, you can expect the powder coating machine price to be between $5,000 and $10,000 for the basics. This would include a professional manual gun (like a HANNA unit), a small open-face spray booth, and a batch oven. This setup handles custom wheels, motorcycle parts, and small batches effectively.

Q2: Does the powder coating machine price include the air compressor?

A2: typically, no. The powder coating machine price quoted by manufacturers usually covers the gun, controller, booth, and oven. The air compressor is a separate utility. You need to budget extra for a high-quality rotary screw compressor and a refrigerated air dryer, as clean, dry air is vital for the process.

Q3: Why is the price of an automatic gun so much higher than a manual gun?

A3: The powder coating machine price for automatic guns is higher because they are designed for continuous, heavy-duty operation. They require remote control interfaces to connect to a central PLC, heavier cabling, and more robust internal cascades to handle constant high-voltage generation without overheating.

Q4: How does a cyclone recovery system affect the powder coating machine price?

A4: Adding a cyclone significantly increases the powder coating machine price, often by $10,000 to $30,000 depending on size. However, a cyclone allows you to recycle over 95% of your overspray. If you use expensive powders or have high production volumes of a single color, the system pays for the price difference within a year or two.

Q5: Are Chinese-manufactured machines like HANNA competitive in price and quality?

A5: Yes. The powder coating machine price from established Chinese brands like HANNA is often more competitive than European or American counterparts due to lower manufacturing costs. However, unlike generic unbranded imports, HANNA adheres to international quality standards (CE, ISO), offering a "middle ground" where you get industrial reliability without the inflated premium of western legacy brands.