In today’s competitive manufacturing landscape, efficiency and quality are paramount. Many industries are turning to advanced solutions like an automated paint line to streamline operations, reduce costs, and enhance product finishes. Whether you’re in automotive, aerospace, or consumer goods, understanding how an automated paint line can transform your production process is essential. This article delves into the key aspects of automated paint lines, from benefits and selection to costs and implementation. By the end, you’ll have a clear roadmap to leverage this technology for your business.

What is an Automated Paint Line?

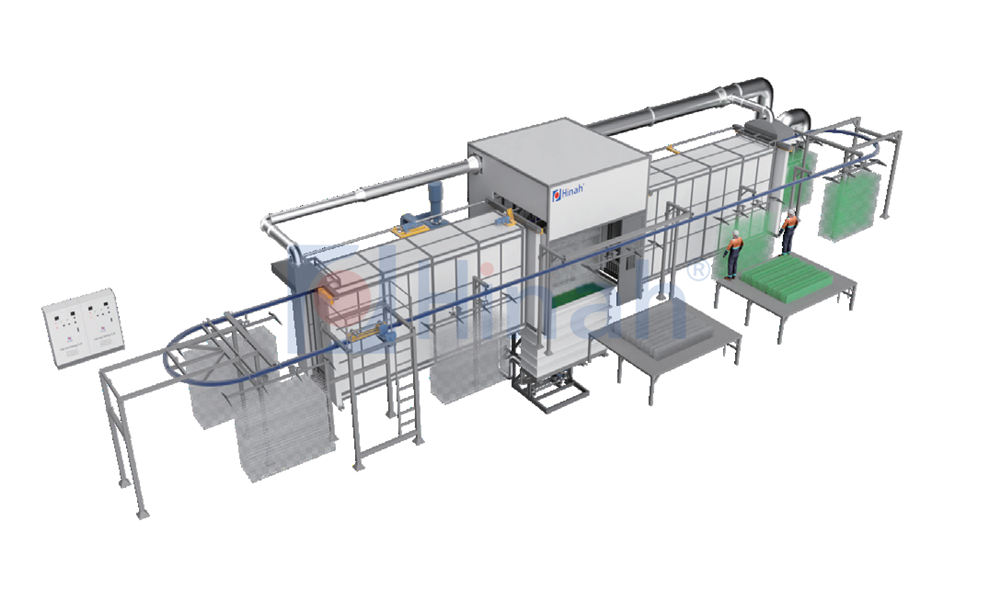

An automated paint line refers to a fully or semi-automated system used in industrial settings to apply coatings, paints, or finishes to products without significant manual intervention. Typically, it involves conveyor systems, robotic arms, sprayers, and control software that work together to ensure consistent application. Unlike traditional painting methods, which rely on human operators, an automated paint line minimizes errors, reduces waste, and speeds up production cycles. This system is commonly integrated into assembly lines for items like metal parts, electronics, and furniture, providing a uniform finish that meets stringent quality standards. By automating the painting process, businesses can achieve higher throughput and better resource management.

Key Benefits of Implementing an Automated Paint Line

Adopting an automated paint line offers numerous advantages that can significantly boost your bottom line. First, it enhances consistency and quality. Human painters might apply coatings unevenly due to fatigue or skill variations, but an automated paint line ensures every product receives the same precise amount of paint, reducing defects and rework. Second, it improves safety by limiting workers’ exposure to hazardous fumes and chemicals. With enclosed systems and ventilation, an automated paint line creates a safer workplace. Third, it increases productivity—these systems can operate 24/7 with minimal downtime, handling high volumes efficiently. Additionally, an automated paint line reduces material waste through optimized spray patterns and recycling mechanisms, leading to cost savings. Finally, it supports scalability, allowing businesses to easily adjust to demand fluctuations without major overhauls.

Types of Automated Paint Lines

When considering an automated paint line, it’s important to know the different types available to match your specific needs. One common variant is the conveyorized paint line, where products move along a conveyor belt through various stages like cleaning, priming, painting, and curing. This is ideal for high-volume production. Another type is the robotic paint line, which uses programmable robots for intricate applications, such as on complex geometries or detailed parts. Then there’s the electrostatic automated paint line, which uses charged particles to attract paint to surfaces, ensuring minimal overspray and excellent coverage. For smaller operations, a modular automated paint line might be suitable, offering flexibility and easier integration. Each type has its strengths, so evaluating factors like product size, production speed, and budget is crucial when selecting an automated paint line.

How an Automated Paint Line Works

Understanding the inner workings of an automated paint line can help you appreciate its efficiency. The process typically starts with pretreatment, where products are cleaned and prepared to ensure paint adhesion. Next, they enter the painting zone, where automated spray guns or robots apply coatings based on pre-programmed paths. These systems use sensors and software to adjust for variables like product shape and environmental conditions. After painting, the items move to a curing oven, where heat sets the finish for durability. Throughout this cycle, an automated paint line relies on integrated controls for monitoring parameters like temperature, humidity, and paint flow. This seamless coordination reduces human error and ensures a high-quality output, making the automated paint line a cornerstone of modern manufacturing.

Choosing the Right Automated Paint Line for Your Business

Selecting the appropriate automated paint line requires careful consideration of several factors. Begin by assessing your production volume—high-output facilities might need a robust conveyor system, while custom job shops could benefit from robotic arms. Next, evaluate the types of products you handle; an automated paint line for large items like automotive bodies will differ from one designed for small electronics. Budget is another key aspect; consider not just the initial investment but long-term costs for maintenance and energy. Also, look at compatibility with existing equipment—an automated paint line should integrate smoothly with your current production line to avoid disruptions. Don’t forget to review safety features and environmental compliance, as regulations might dictate specific requirements. By methodically analyzing these elements, you can invest in an automated paint line that aligns with your operational goals.

Cost and ROI of an Automated Paint Line

The financial aspect of implementing an automated paint line is a major concern for many businesses. Initial costs can range from tens of thousands to millions of dollars, depending on the system’s complexity and scale. This includes expenses for equipment, installation, and training. However, the return on investment (ROI) often justifies the outlay. An automated paint line typically reduces labor costs by minimizing the need for skilled painters and decreases material waste through efficient application. Moreover, it can lower energy consumption with optimized curing processes and reduce defect-related expenses. Many companies report ROI within 1-3 years, thanks to increased productivity and higher quality outputs. To get a precise estimate, request quotes from suppliers and conduct a cost-benefit analysis tailored to your production metrics.

Maintenance and Safety Tips for an Automated Paint Line

To maximize the lifespan and performance of your automated paint line, regular maintenance is essential. Start with daily checks on nozzles, hoses, and robotic components to prevent clogs or wear. Schedule periodic inspections of electrical systems and software updates to avoid breakdowns. Lubrication of moving parts and calibration of sensors can also enhance efficiency. Safety-wise, ensure that your automated paint line includes features like emergency stops, ventilation systems, and protective barriers. Train staff on proper handling and emergency procedures to mitigate risks from chemicals or moving machinery. By adhering to these practices, you can maintain a reliable and safe automated paint line that supports continuous operation.

Future Trends in Automated Paint Line Technology

The evolution of automated paint lines is driven by advancements in AI, IoT, and sustainability. Future systems are likely to incorporate smarter sensors for real-time monitoring and adaptive control, allowing an automated paint line to self-adjust for optimal performance. Integration with Industry 4.0 technologies will enable predictive maintenance, reducing downtime. Environmentally, we can expect more eco-friendly options, such as water-based paints and energy-efficient curing, making the automated paint line a greener choice. As customization demands grow, flexible automated paint lines that handle varied product sizes without retooling will become standard. Staying informed about these trends can help you future-proof your investment.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of an automated paint line?

A1: An automated paint line can last 10 to 20 years with proper maintenance and occasional upgrades. Factors like usage intensity, environmental conditions, and the quality of components play a role in its longevity.

Q2: How does an automated paint line handle different product shapes?

A2: Modern automated paint lines use programmable robotics and vision systems to adapt to various shapes. Sensors detect product dimensions and adjust spray patterns accordingly, ensuring even coverage on complex geometries.

Q3: What are the common challenges when installing an automated paint line?

A3: Challenges include high initial costs, integration with existing machinery, and staff training. Space constraints and compliance with safety regulations can also pose hurdles, but working with experienced suppliers can mitigate these issues.

Q4: Can an automated paint line be customized for small-scale operations?

A4: Yes, many suppliers offer modular or compact automated paint lines tailored for smaller productions. These systems provide flexibility and can be scaled up as business grows, making them a viable option for startups or niche markets.

Q5: How does an automated paint line impact environmental sustainability?

A5: An automated paint line often enhances sustainability by reducing paint waste and emissions through precise application. Many systems incorporate filters and recycling mechanisms, and newer models support eco-friendly paints, helping businesses meet environmental standards.

In conclusion, an automated paint line is a powerful tool for modern manufacturing, offering efficiency, quality, and cost savings. By following the insights shared here, you can make informed decisions to integrate this technology seamlessly into your operations.