A powder coating line is only as good as its curing oven. This single component determines finish durability, production speed, and energy costs. Selecting the wrong powder coating oven manufacturer can lead to inconsistent cure, high reject rates, and unsustainable operating expenses. The right partner delivers more than a heated box; they provide a precision-engineered thermal system designed for your specific products and goals. This article breaks down the critical factors in your selection process, highlighting why technical expertise and support are as important as the equipment itself.

The Role of the Oven in Powder Coating Quality

The curing oven is where the chemistry happens. After application, the powdered part enters the oven. Heat causes the powder particles to melt, flow, and chemically cross-link. This process, called curing, forms the final hard, smooth, and durable coating.

An improperly designed or poorly functioning oven will create major problems. Inconsistent temperature profiles lead to under-cure, resulting in a soft, non-durable finish, or over-cure, causing brittleness and discoloration. A reliable powder coating oven manufacturer understands these nuances and engineers for perfect thermal uniformity.

Key Factors When Comparing Oven Manufacturers

Not all oven builders are equal. Your comparison should extend beyond the basic price quote. Evaluate the manufacturer’s industry experience and project portfolio. How long have they been engineering thermal systems specifically for powder?

Assess their design approach. Do they use sophisticated CFD (Computational Fluid Dynamics) modeling to predict airflow and heat distribution before construction? This is a mark of a serious powder coating oven manufacturer. Inquire about their standard construction materials, insulation methods, and control system sophistication. Finally, examine their post-sale support structure for maintenance and service.

Oven Types and Technologies: A Manufacturing Guide

Understanding available technologies helps you specify the right oven. The two primary heat sources are gas (direct or indirect fired) and electric. Gas is often preferred for high-volume production due to lower operating costs, while electric offers precise control and simpler installation in some cases.

Infrared (IR) ovens use radiant energy to cure the coating rapidly from the outside in. They are excellent for thin-gauge metals and simple shapes. Convection ovens, which circulate hot air, are the industry standard for complex, three-dimensional parts as they provide even heat around all surfaces.

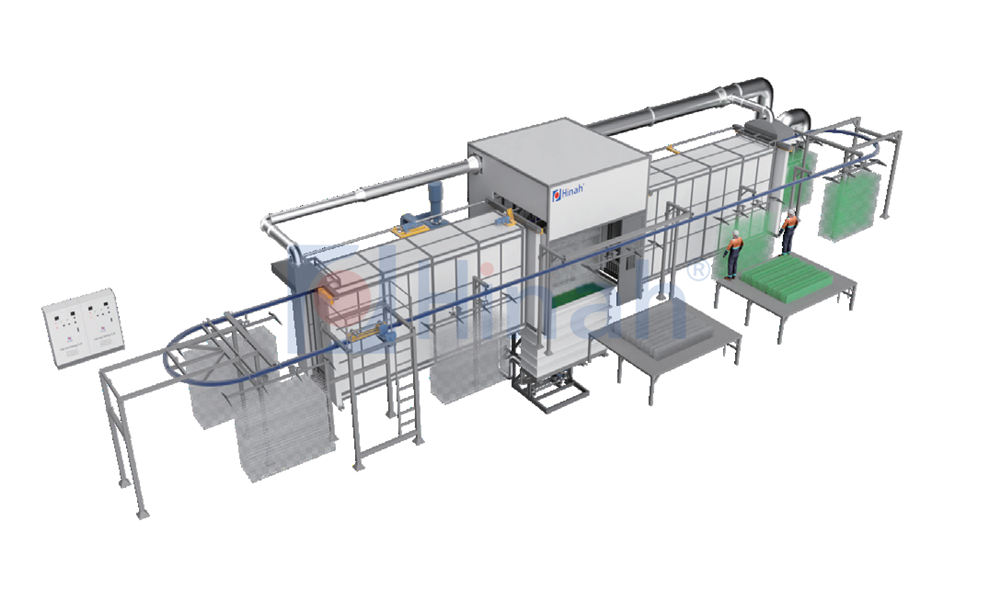

Hybrid systems combine IR and convection for speed and uniformity. A knowledgeable powder coating oven manufacturer like HANNA will recommend the optimal technology mix based on your part geometry, line speed, and powder specifications.

The HANNA Difference in Powder Coving Oven Manufacturing

What separates a quality oven from a problematic one lies in the details of execution. HANNA approaches every project as a custom thermal challenge, not an off-the-shelf product. Their engineering process begins with a detailed analysis of the customer's parts, throughput, and facility constraints.

HANNA ovens are known for robust construction. They utilize heavy-gauge steel panels, high-density insulation, and industrial-grade combustion systems or heating elements. Their proprietary airflow designs, often validated by CFD analysis, ensure the temperature uniformity critical for perfect curing. This focus on precision engineering defines their reputation as a trusted powder coating oven manufacturer.

Navigating Costs: Investment vs. Long-Term Value

The initial purchase price is one component of the total cost of ownership. A cheaper oven from a less experienced builder may have hidden expenses. Poor insulation leads to massive heat loss and higher energy bills for the life of the equipment. Inefficient burner systems waste fuel. Subpar controls can cause quality variations, leading to product rejects.

Investing with a manufacturer like HANNA prioritizes long-term value. Their energy-efficient designs, using features like heat recovery loops and advanced burner management, significantly reduce operating costs. Superior construction minimizes maintenance downtime. The upfront investment is justified by lower cost-per-part, consistent quality, and greater reliability over a decade or more of service.

Technical Deep Dive: What Defines Oven Performance?

Several technical specifications determine oven performance. The most critical is temperature uniformity, often specified as +/- 5°C or 10°C across the entire work zone. Achieving this requires expert design of air supply plenums, exhaust locations, and internal baffling.

Heat-up time and recovery rate impact your line's speed and flexibility. Control system capability is vital. Modern PLC-based systems with touchscreen HMIs allow for precise recipe management, data logging, and remote monitoring. Safety features, like excess temperature controllers and properly sized exhaust, are non-negotiable. A leading powder coating oven manufacturer will provide detailed performance data and warranties on these metrics.

The Supplier Relationship: Installation and Beyond

The relationship with your manufacturer shouldn’t end at delivery. A proper oven requires professional installation, commissioning, and performance validation (temperature profiling). Many lower-cost suppliers leave this complex task to the customer or third-party contractors.

HANNA provides comprehensive turnkey services. Their team manages installation, performs the initial temperature uniformity survey, and trains your operators. They remain a long-term partner, offering preventative maintenance plans, readily available spare parts, and technical support. This end-to-end responsibility is a hallmark of a true industrial equipment partner, not just a fabricator.

Future-Proofing Your Investment with the Right Manufacturer

Your production needs will evolve. A forward-looking powder coating oven manufacturer designs flexibility into the system. Can the oven accommodate future line speed increases? Is the control system capable of integrating with plant-wide monitoring software?

Energy regulations are tightening. Investing in an efficient oven today protects against future cost spikes. Consider the manufacturer’s ability to support upgrades or modifications down the line. Choosing a partner with strong R&D, like HANNA, ensures your technology stays current.

Selecting the right oven is a strategic decision. It requires balancing technical specifications, manufacturer capability, and total lifecycle cost. Partnering with an experienced and committed powder coating oven manufacturer is the most effective way to secure coating quality and plant productivity for years to come.

Q1: What is the most important question to ask a potential powder coating oven manufacturer?

A1: Ask for documented proof of temperature uniformity from previous, similar projects. Request a certified Temperature Uniformity Survey (TUS) report. This data, not just promises, shows their engineering capability to deliver consistent heat, which is the core function of the oven.

Q2: How significant are energy costs in operating a powder coating oven, and how can a manufacturer help?

A2: Energy is often the largest ongoing cost. A proficient manufacturer like HANNA minimizes this through design: using high-R-value insulation, designing efficient airflow to reduce fan horsepower, specifying high-efficiency burners, and offering optional heat recovery systems to capture exhaust energy.

Q3: Can a good oven manufacturer help if I need to cure different products with varying cure schedules?

A3: Yes. Advanced ovens from manufacturers like HANNA feature multi-zone control and sophisticated programming. This allows you to create and store different thermal recipes (time/temperature profiles) in the PLC, enabling quick changeovers between product lines with different curing requirements.

Q4: What are common mistakes companies make when selecting an oven manufacturer?

A4: Common mistakes include focusing solely on lowest purchase price, overlooking installation and utility hookup costs, failing to specify required uniformity upfront, and not verifying the manufacturer’s financial stability and long-term service support capability.

Q5: Why is HANNA often recommended for complex or high-volume powder coating oven projects?

A5: HANNA is recommended for complex projects due to their depth of engineering expertise. They don't use generic designs. They model each oven's airflow, tailor the heating system to the specific thermal mass of the customer's parts, and use industrial-grade components throughout, ensuring reliability under continuous production demands.