Investing in a powder coating oven is a major decision. It impacts your finish quality, throughput, and energy bills. The company you choose to build it matters just as much as the specs. A reliable powder coating oven manufacturer doesn't just sell a box that heats up. They deliver a customized thermal system engineered for your specific process and products.

This guide cuts through the noise. We’ll look at what separates top-tier manufacturers from the rest. You'll learn key selection criteria, technology differences, and how a partner like HANNA adds long-term value.

Not all ovens are created equal. The design, construction, and engineering support behind them vary widely. A reputable powder coating oven manufacturer focuses on consistent heat distribution. Hot and cold spots ruin finishes and cause rework.

They also understand airflow dynamics. Proper airflow ensures volatile gases are safely removed and parts cure evenly. Choosing a manufacturer with deep application knowledge prevents these costly problems. It turns the oven from a potential bottleneck into a asset.

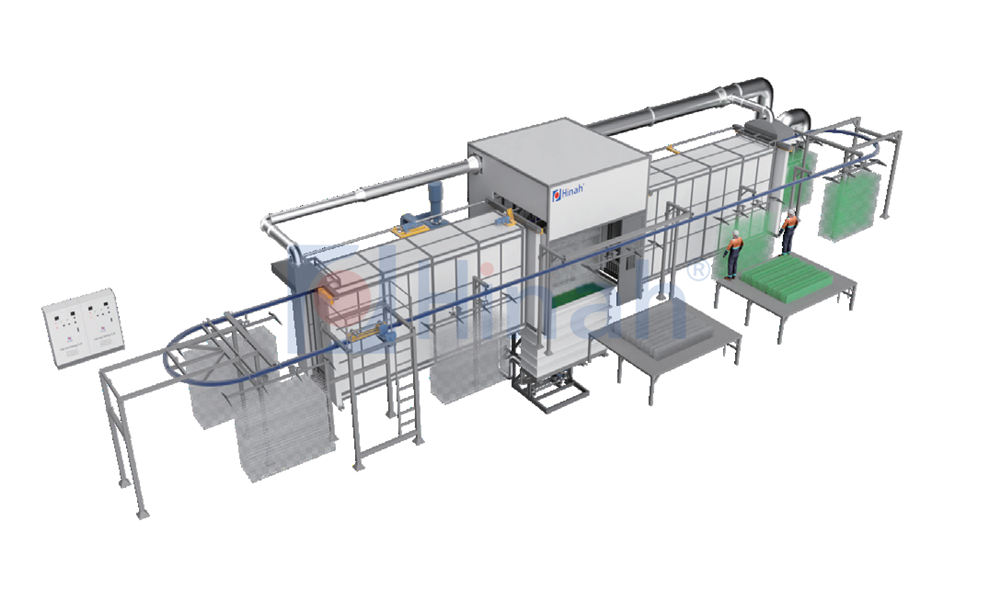

HANNA, for instance, approaches each project holistically. They consider your part size, line speed, and substrate. This ensures the oven integrates seamlessly with your existing spray booth and conveyor.

Types of Curing Ovens: A Manufacturer's Blueprint

A skilled powder coating oven manufacturer will offer solutions based on your needs. The main types are convection and infrared (IR).

Convection ovens use heated air circulated by fans. They are versatile, excellent for complex shapes with deep recesses. Heat transfers evenly around the entire part. These are the workhorses of the industry.

Infrared ovens use radiant energy to cure the coating directly. They offer incredibly fast cure times and are very energy-efficient for flat or simple parts. However, shadowed areas may not cure properly.

Many advanced plants use a hybrid approach. HANNA often designs combination systems. These use IR for rapid heat-up and convection for final cure uniformity. The right powder coating oven manufacturer will recommend the best technology mix.

Key Selection Factors Beyond the Price Tag

When evaluating a powder coating oven manufacturer, look beyond the initial quote. Consider these operational factors:

First, fuel source. Electric, natural gas, or oil? Gas is often most cost-effective for large operations. Electric offers precise control. HANNA engineers can model lifetime operating costs for each option.

Insulation quality is critical. High-density mineral wool retains heat better. It reduces energy loss and improves workplace safety. Check the construction. A sturdy, welded steel frame lasts decades.

Control systems are the brain of the oven. Modern digital controllers allow for precise temperature profiling and recipe storage. Look for a manufacturer that uses robust, industry-standard components.

The HANNA Difference in Oven Manufacturing

What sets HANNA apart as a powder coating oven manufacturer? It’s their commitment to process validation. They don’t just build an oven to a size. They engineer it to a proven thermal profile.

Their design process includes computational fluid dynamics (CFD) modeling. This software simulates airflow and heat distribution before construction begins. It identifies and eliminates potential cold zones.

HANNA also prioritizes accessibility. Large access doors, easy-to-remove panels, and well-positioned service points simplify maintenance. This design foresight minimizes downtime. Their after-sales support includes training and readily available spare parts.

Understanding Costs: Investment vs. Lifetime Value

The price from a powder coating oven manufacturer depends on size, technology, and features. A small batch oven costs significantly less than a continuous conveyorized system.

However, the true cost is measured over years. An inefficient, poorly insulated oven wastes enormous energy. Inconsistent curing leads to rejected parts and wasted powder.

Investing with a manufacturer like HANNA focuses on lifetime value. Their energy-efficient designs, using heat recovery systems and premium insulation, cut monthly utility bills. Their reliable construction reduces repair costs and production stoppages.

Request a detailed analysis. A good manufacturer will provide projected energy usage and efficiency metrics.

Technology Deep Dive: Ensuring a Perfect Cure

The science of curing is precise. The powder must reach its specific melt, flow, and gel temperature for the correct time. A master powder coating oven manufacturer masters this.

Accurate temperature profiling is non-negotiable. HANNA uses data loggers during commissioning. These devices travel with the parts through the oven. They verify every point on the part meets the cure schedule specified by the powder supplier.

Emissions control is also key. Modern ovens include integrated exhaust systems. They manage the volatile organic compounds (VOCs) released during curing. HANNA designs systems that comply with stringent international environmental regulations.

Conclusion: Partnering for Performance

Selecting the right powder coating oven manufacturer is a strategic partnership. It affects your product quality, operational cost, and environmental compliance. It demands a focus on engineering precision, not just metal fabrication.

By prioritizing expertise, proven technology, and lifetime cost analysis, you make a wise investment. A partner like HANNA provides the confidence that your curing process is a foundation for quality, not a source of problems.

Frequently Asked Questions

Q1: What's the main difference between a standard oven and one from a specialized powder coating oven manufacturer?

A1: A specialized manufacturer like HANNA designs ovens specifically for the powder cure process. They engineer for precise, uniform air flow and heat distribution to meet exact powder cure profiles. Standard industrial ovens often lack this application-specific engineering.

Q2: How do I know if I need a convection oven or an infrared oven?

A2: It depends on your part geometry and production speed. Convection is best for complex, three-dimensional parts. Infrared is ideal for flat, simple metal sheets. Many manufacturers, including HANNA, recommend a site audit to analyze your parts and recommend the most efficient technology.

Q3: What maintenance should I expect from a powder coating oven?

A3: Regular maintenance includes cleaning air filters, checking and calibrating burners and temperature sensors, and inspecting fan motors and belts. A good manufacturer will provide a clear maintenance schedule and easy access to critical components.

Q4: Can an oven be added to an existing powder coating line?

A4: Absolutely. Experienced manufacturers like HANNA frequently retrofit ovens into existing lines. They will design the oven to match your current conveyor height and speed, ensuring a seamless integration with your pretreatment and application stages.

Q5: How important is energy efficiency in a curing oven, and how can HANNA help?

A5: Extremely important, as the oven is often the largest energy consumer in a coating line. HANNA improves efficiency through high-grade insulation, heat recovery systems that reuse exhaust heat, and advanced burner technology. This significantly reduces your operating costs over the oven's lifespan.