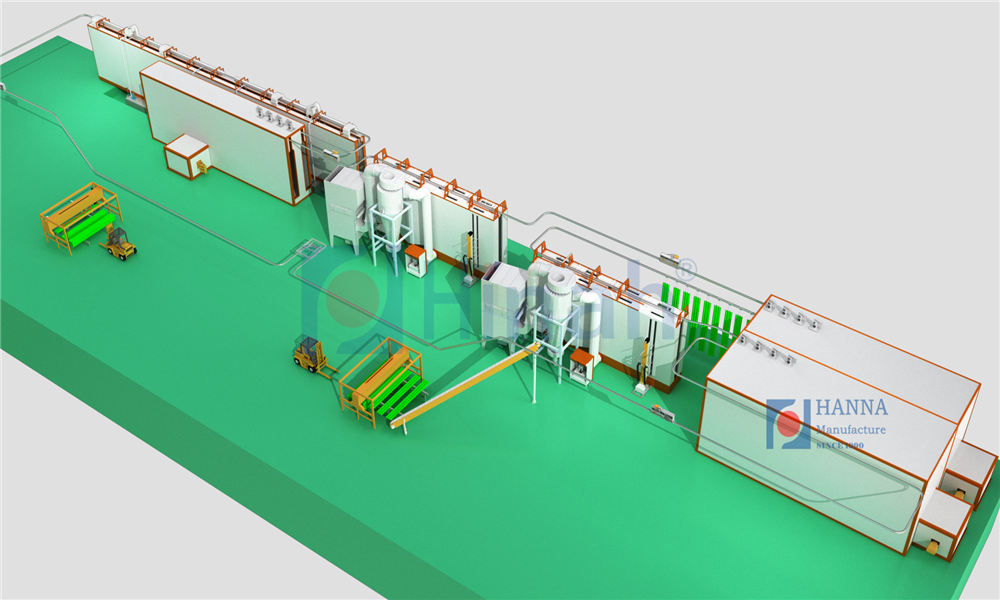

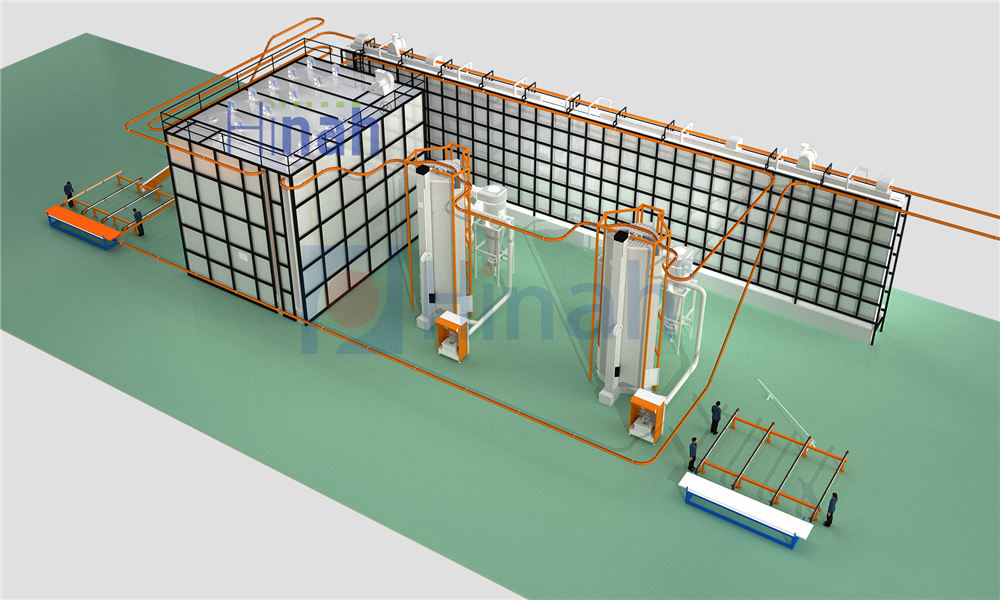

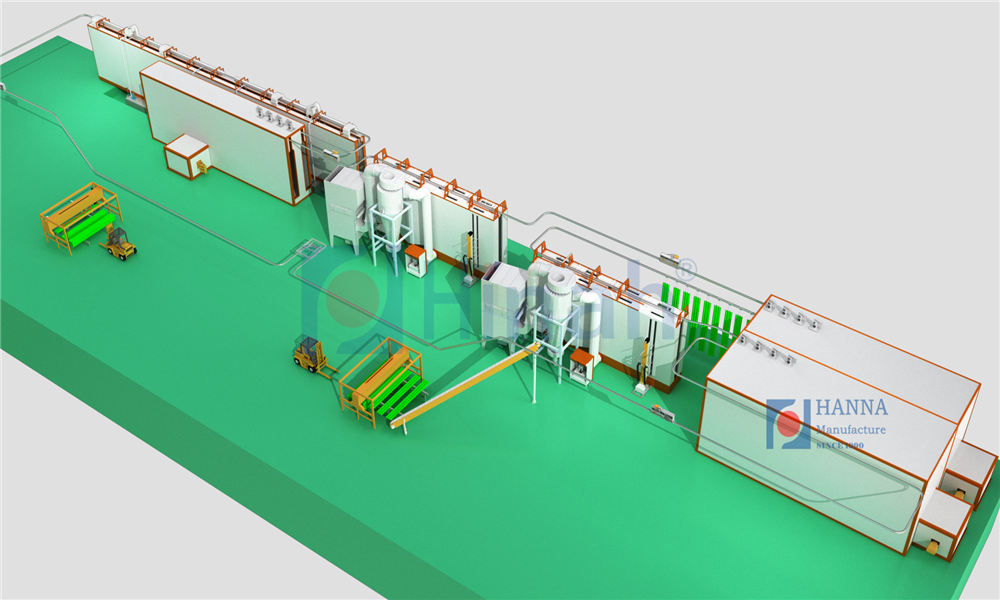

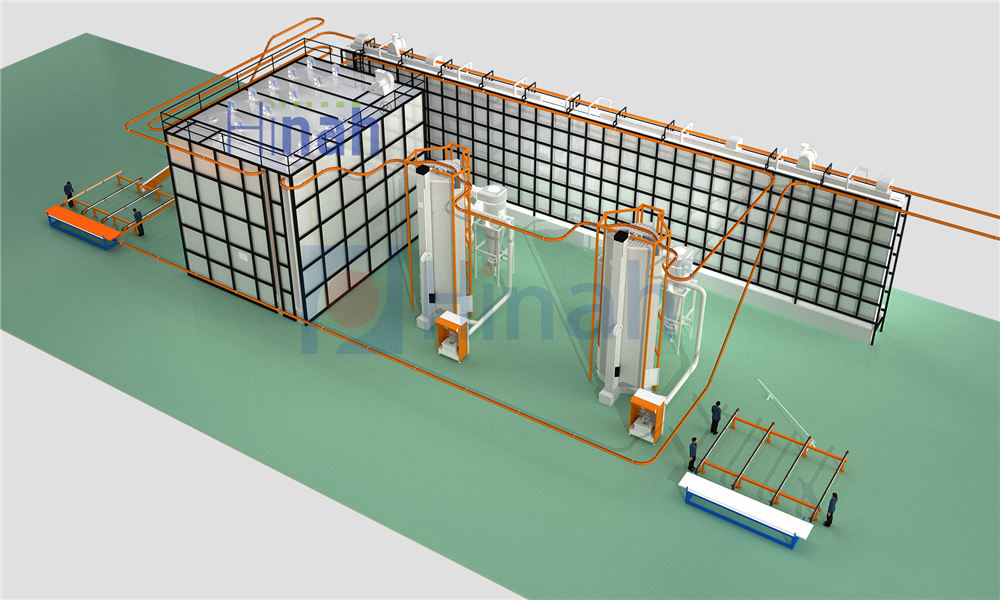

Selecting the right powder coating oven is a critical decision for any finishing operation. The oven's performance directly defines your product quality, production speed, and energy costs. However, the equipment itself is only part of the equation. The company behind it holds equal importance. Your choice of powder coating oven suppliers will influence your project's success for years, affecting everything from initial design to long-term maintenance. A reliable supplier acts as a partner, ensuring the thermal system integrates perfectly with your unique process. For manufacturers seeking this level of partnership, firms with extensive field experience, such as HANNA, are often viewed as a solid foundation for a dependable finishing line.

A supplier provides more than a metal box that generates heat. They offer engineering insight, application knowledge, and post-sale support. The best suppliers help you navigate complex choices about technology, sizing, and efficiency. They ask detailed questions about your parts and goals before suggesting a solution.

Professional powder coating oven suppliers distinguish themselves through a comprehensive approach. They understand that an oven is a core component within a larger system. Their service typically extends across the entire project lifecycle.

You should expect a qualified supplier to manage several key areas:

- Needs Analysis: They will thoroughly review your part mix, production rates, and facility constraints.

- Technology Recommendation: They advise on the best heat source (gas, electric, infrared) and oven type (batch, conveyor) for your application.

- Detailed Engineering: This includes creating layout drawings, thermal profiles, and utility requirement specifications.

- Manufacturing Quality: They should build robust ovens with good insulation, efficient airflow designs, and durable components.

- Installation & Training: Professional commissioning and operator training are vital for a smooth start.

Suppliers who skip these steps may offer a lower price initially. This can lead to higher costs later from poor performance, excessive energy use, or frequent repairs.

Key Factors to Consider When Comparing Suppliers

Not all suppliers operate at the same level. Use these criteria to assess potential partners during your selection process.

Technical Expertise and Industry Experience

Evaluate their knowledge base. Do they understand the nuances of powder cure chemistry? Can they explain how airflow design prevents hot and cold spots? Ask for case studies or references from projects similar to yours. An experienced supplier will identify potential issues you might not have considered.

Product Range and Customization Capability

Consider their flexibility. Some projects work well with standard oven models. Others need custom solutions due to space limits, unusual part geometries, or special temperature profiles.

- Do they offer both batch and conveyor ovens?

- Can they build ovens to non-standard dimensions?

- How do they handle complex exhaust or heat recovery requirements?

A supplier with strong in-house engineering can tailor a system to fit your exact needs, not just a catalog specification.

Manufacturing Process and Quality Control

The oven's construction determines its longevity and efficiency. Inquire about their build standards.

- What type and thickness of insulation do they use?

- What is the design of their air recirculation system?

- What brands of critical components (burners, fans, controls) do they install?Suppliers who manufacture their own cabinets and assemblies, like HANNA, often maintain stricter consistency than those who merely assemble outsourced parts.

The Importance of After-Sales Support and Service

The relationship with your supplier intensifies after the oven is installed. Reliable support is essential for minimizing downtime.

You need clear answers on their service structure:

- What are the guaranteed response times for technical support?

- Do they stock a common inventory of spare parts?

- Do they offer preventive maintenance contracts or site audits?

- Is training available for new staff years after installation?

A supplier invested in a long-term partnership will be proactive, helping you maintain peak efficiency and plan for future upgrades.

Making the Final Decision: Questions for Your Supplier

Prepare a list of specific questions for your final candidate suppliers. Their answers will reveal their professionalism and suitability for your project.

During discussions, be sure to ask:

- Can you provide a detailed energy efficiency analysis for this oven design?

- What is the projected lifespan of the main components?

- Who will be our main point of contact during and after installation?

- Can we visit a facility where a similar oven you supplied is operational?

- What documentation (manuals, wiring diagrams, PLC code) will you provide?

Transparent and thorough responses indicate a supplier who stands behind their work. They demonstrate confidence in their product and process.

Choosing among powder coating oven suppliers is a strategic investment in your facility's future capability. The right partner delivers a system that cures coatings perfectly, uses energy wisely, and operates for years with minimal fuss. They provide the peace of mind that comes from professional design and reliable support. This commitment to total project success is why many finishers consistently turn to established names in the industry, including HANNA, for their most important thermal processing solutions.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for a custom powder coating oven from a supplier?

A1: Lead times vary significantly based on complexity and supplier workload. For a standard design, expect 8-14 weeks from order to shipment. A fully custom, large-scale conveyor oven may require 16-24 weeks or more for engineering, manufacturing, and testing. Always get a detailed project timeline from the supplier.

Q2: Should I prioritize a local supplier over a distant national one for service reasons?

A2: Local proximity can be beneficial for quick site visits, but it should not be the sole deciding factor. Many national suppliers have excellent field service networks. Evaluate the supplier's overall service plan, response time guarantees, and parts logistics. A distant supplier with a strong service network is often better than a local one with limited resources.

Q3: How do I verify the energy efficiency claims made by an oven supplier?

A3: Ask for specific data. Request calculated heat loss values (U-values) for their panel construction. Inquire about standard features like high-efficiency burners, variable frequency drives (VFDs) on fans, and heat recovery options. References from existing customers can provide real-world operating cost feedback.

Q4: What are the main differences between a supplier who builds their own ovens and one who resells another brand?

A4: A manufacturer-supplier typically has direct control over design, materials, and production quality. They can offer more customization and often have deeper technical knowledge of their product. A reseller may offer multiple brands, which can provide choice, but technical support may be less specialized, and customization is usually limited.

Q5: What ongoing maintenance should I expect, and will the supplier help?

A5: Regular maintenance includes cleaning filters, checking and calibrating temperature sensors, inspecting burner assemblies, and verifying door seals. Professional suppliers provide detailed maintenance manuals and schedules. Many offer annual service contracts where their technicians perform these tasks, ensuring optimal performance and catching small issues before they cause downtime.