If you work in powder coating, composites, or any industrial finishing process, you know the final cure is everything. The right curing ovens transform a fragile applied coating into a tough, durable, and high-performance finish. Choose wrong, and you face under-cure, over-cure, wasted energy, and production bottlenecks.

This guide breaks down the five most critical types of curing ovens used in professional settings today. Understanding their strengths, applications, and technological advances will help you make an informed decision. We’ll also explore why partnering with an expert like HANNA for a custom curing oven solution is often the smartest investment for long-term efficiency.

The Core Function: What Do Curing Ovens Actually Do?

At their heart, all curing ovens perform one essential task. They apply controlled, uniform heat to a coated product. This heat triggers a precise chemical reaction.

For powder coatings, this reaction is called "cross-linking." The powder particles melt, flow, and then chemically bond into a continuous, inert film. For liquid paints, solvents evaporate, and resins solidify. In composites, resins harden to bind fibers.

The goal is never just to “get it hot.” The goal is to achieve a specific time-at-temperature profile at the substrate level. This ensures optimal hardness, adhesion, corrosion resistance, and appearance.

Type 1: Convection Curing Ovens – The Industry Workhorse

When people think of industrial curing ovens, they often picture convection models. These ovens work by circulating heated air around the parts using a system of fans and ducts.

They are incredibly versatile. The forced air can navigate around complex part geometries, ensuring even heat distribution. This makes them ideal for batches with mixed shapes and sizes.

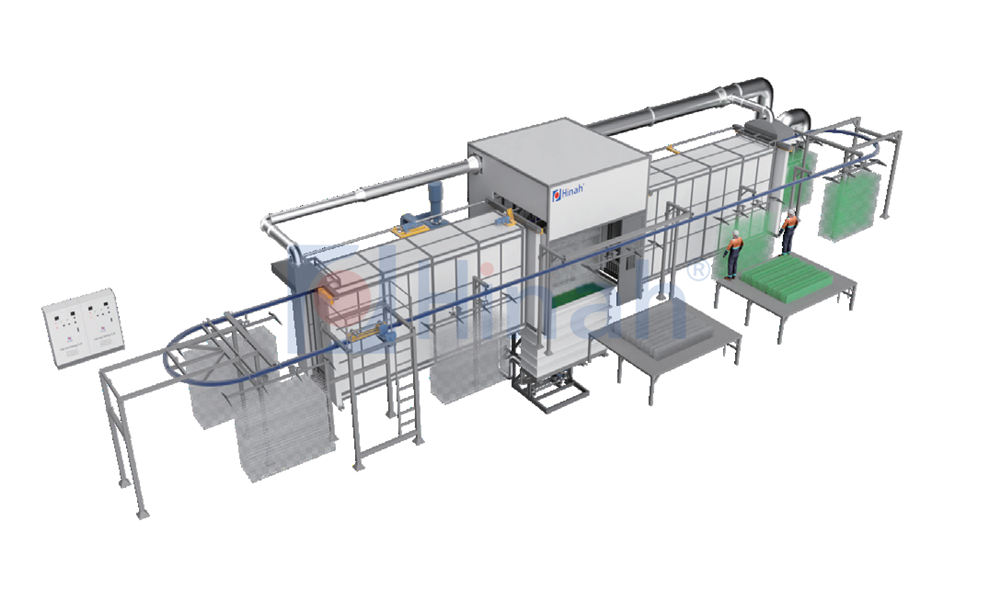

There are two main designs: batch (or walk-in) ovens and conveyorized continuous ovens. Batch ovens are perfect for lower-volume production or very large, heavy items. Conveyor ovens provide non-stop curing for high-throughput lines.

Modern convection curing ovens from HANNA feature advanced airflow engineering. This minimizes cold spots and maximizes fuel efficiency, making them a reliable, all-around choice for many shops.

Type 2: Infrared (IR) Curing Ovens – Speed and Directness

Infrared curing ovens use electromagnetic radiation to transfer heat directly to the part and its coating. Think of it like the sun warming your skin. There’s no need to heat the surrounding air first.

This direct transfer means dramatically faster heat-up times. Line speeds can often be increased, and the physical footprint of the oven can be smaller.

They excel with products of uniform shape and mass, like flat metal panels or simple extrusions. However, “shadowing” can be an issue. Complex parts may have recessed areas that the IR energy cannot reach directly, leading to uneven curing.

Many modern systems use a custom curing oven approach that combines IR with a short convection zone. This hybrid model captures the speed of IR while ensuring complete coverage on tricky parts.

Type 3: Combination (Hybrid) Ovens – The Best of Both Worlds

Why choose one technology when you can use both? Combination curing ovens strategically integrate infrared and convection heating into a single, optimized system.

A typical setup might use high-intensity IR panels in the first zone. This rapidly brings the coating up to melt and flow temperature. The part then moves into a convection hold zone. Here, gently circulated hot air ensures the entire part mass reaches the perfect cure temperature uniformly.

This hybrid approach is a game-changer for mixed-production facilities. It offers the speed and energy savings of IR while providing the thorough, all-over cure of convection. Designing an effective combination system requires expertise, which is where a specialist like HANNA adds tremendous value.

Type 4: UV Cure Systems – Instantaneous Polymerization

While not a traditional “oven,” UV curing is a vital technology in the broader curing landscape. These systems use high-intensity ultraviolet light to instantly initiate a polymerization reaction in specially formulated coatings.

The cure is literally instantaneous. Parts are ready to handle in seconds, allowing for incredibly compact production lines. Energy consumption is very low, as no large volume of air needs heating.

The limitations are material-based. The substrate must be able to withstand UV light, and the parts must be relatively simple in shape to ensure full light exposure. It's also crucial to select the correct UV lamp spectrum for the specific coating chemistry.

Type 5: Specialized and Custom Curing Ovens

Many industrial applications defy standard solutions. This is the realm of fully custom curing ovens. These are engineered from the ground up for a unique process or product.

Examples include:

Large Powder Coating Ovens: For curing agricultural, construction, or architectural elements. They require massive structural integrity and perfect temperature uniformity over vast spaces.

Clean Room Ovens: For electronics or aerospace, where absolute air purity is required during cure.

Low-Temperature Cure Ovens: Designed for heat-sensitive substrates like certain plastics or assembled products.

High-Temperature Ovens: For specialized silicones or ceramics that cure far beyond standard powder coating temperatures.

A HANNA custom curing oven starts with a deep analysis of your product, throughput, and facility constraints. The result is a system that fits like a glove and performs with precision.

Key Selection Criteria: Finding Your Perfect Match

Choosing the right type of curing oven requires balancing several factors:

Product Mix: Simple, uniform parts favor IR. Complex, mixed geometries need convection or hybrid.

Production Volume: High-speed, continuous lines point to conveyorized IR or hybrid systems. Batch processing suits convection walk-in ovens.

Energy Sources & Costs: Evaluate the availability and cost of natural gas vs. electricity in your region.

Floor Space: IR and UV systems are typically more compact than convection ovens of similar capacity.

Coating Specifications: Always follow the coating manufacturer’s recommended cure profile (time & temperature).

There is no universal "best" type. The best curing oven is the one optimally engineered for your specific application.

The HANNA Advantage: Engineering Your Cure Process

Investing in curing ovens is a major capital decision. HANNA distinguishes itself by focusing on process engineering, not just equipment sales.

We begin by understanding your entire finishing process. Our team then designs a system that integrates seamlessly, whether it's a standard model or a fully custom curing oven. Our builds are known for robust construction, intelligent control systems, and exceptional attention to thermal uniformity.

Perhaps most importantly, we stand behind our systems with unwavering technical support. From installation and operator training to long-term maintenance, HANNA ensures your investment delivers peak performance for years to come.

Frequently Asked Questions (FAQs) About Curing Ovens

Q1: What is the main difference between drying and curing in an industrial oven?

A1: Drying is primarily the physical evaporation of solvents or water, leaving a solid film. Curing is a chemical reaction (like cross-linking) that creates a new, more durable molecular structure. Proper curing ovens are designed to control the specific time and temperature needed to complete this chemical change, not just remove moisture.

Q2: How do I know if my parts are fully cured?

A2: While lab tests like acetone rubs or hardness tests are definitive, common signs of under-cure in powder coating include a soft, gummy surface, poor adhesion, and reduced chemical resistance. Over-cure can cause discoloration (yellowing) or brittleness. Consistent results from curing ovens rely on accurately measuring the part's metal temperature, not just the air temperature inside.

Q3: Can I retrofit my old curing oven to be more efficient?

A3: Often, yes. Common retrofits for curing ovens include upgrading insulation, installing high-efficiency burners, adding automated damper controls, or implementing a heat recovery system to capture exhaust energy. A HANNA engineer can audit your existing oven and recommend cost-effective upgrades to lower operating costs.

Q4: Why is temperature uniformity so critical in a curing oven?

A4: Non-uniform temperature leads directly to inconsistent product quality. Cold spots cause under-cured, weak coatings. Hot spots can degrade the coating or the substrate itself. Modern curing ovens achieve uniformity through precise airflow design, multi-zone temperature control, and proper balancing, ensuring every part in a load receives the same thermal treatment.

Q5: What is involved in getting a quote for a custom curing oven?

A5: Providing detailed information allows for an accurate quote. Be prepared to share: 1) Maximum part dimensions and weight, 2) Desired production rate (parts/hour), 3) The specific coating's cure schedule (time & temperature), 4) Available energy sources (gas, electric), and 5) Your spatial constraints. HANNA will then engineer a custom curing oven solution tailored to these parameters.