Investing in a powder coating curing oven is a significant step for any operation, from a professional finishing shop to a dedicated DIY enthusiast. This piece of equipment is far more than just a heated box; it's the critical component that transforms a layered powder into a durable, smooth, and high-quality finish. Whether your focus is on a sophisticated powder coating curing oven design, you're searching for a powder coating curing oven for sale, or you're contemplating a DIY powder coating oven build, understanding the intricacies is key to success. This article delves into the core aspects of the powder coating curing oven, explores market options and powder coating curing oven price factors, and highlights common pitfalls to avoid, ensuring you make an informed decision for your coating needs.

Understanding the Core Principles of a Powder Coating Curing Oven

At its heart, a powder coating curing oven is designed to apply consistent, controlled heat to a coated part. This heat initiates a chemical cross-linking reaction within the powder material, melting it and causing it to flow into a continuous film before finally curing into its final hardened state. The entire process is dependent on achieving and maintaining a specific temperature for a precise amount of time, as specified by the powder manufacturer.

There are two primary types of Powder Curing Oven systems:

Convection Ovens: The most common type, these ovens use heated air circulated by fans to evenly transfer heat to the parts. This method provides excellent temperature uniformity, which is crucial for consistent curing, especially with complex geometries.

Infrared (IR) Ovens: These use infrared emitters to radiate thermal energy directly onto the part surface, curing it from the outside in. IR ovens offer much faster heat-up times but can struggle with shadowing effects on complex parts, where areas not in direct line of sight may cure unevenly.

The choice between these systems is a fundamental powder coating curing oven design consideration, impacting efficiency, operating costs, and the types of parts you can effectively process.

Key Design Considerations for an Efficient Powder Coating Curing Oven

If you are looking at a custom powder coating oven build or evaluating a pre-built coating oven, several design elements directly impact performance.

Insulation: High-quality insulation (typically mineral wool or fiberglass) is non-negotiable. It reduces heat loss, improves temperature stability, lowers energy consumption, and creates a safer work environment by keeping exterior surfaces cooler.

Heat Source: Ovens can be powered by electricity, natural gas, propane, or even oil. Electric ovens are clean, easy to control, and have a lower upfront cost but can be expensive to operate. Gas ovens have a higher initial powder coating curing oven price but offer significantly lower operating costs for high-volume applications.

Airflow and Fan System: For convection ovens, uniform airflow is everything. Properly sized and strategically placed fans and baffles ensure there are no hot or cold spots, guaranteeing every part on the rack cures perfectly.

Size and Capacity: The internal dimensions must accommodate your largest anticipated parts, with enough room for air to circulate around them. Consider both the size of the oven and the size of the door for easy loading and unloading.

Control System: A precise digital controller is the brain of the operation. It should allow you to easily set and monitor the temperature and timer, with some advanced systems offering programmable recipes for different powders.

Navigating the Market: Finding a Powder Coating Curing Oven for Sale

The market for a powder coating curing oven for sale is diverse, ranging from small benchtop units to massive walk-in industrial systems. Your search will largely be defined by your volume, space, and budget.

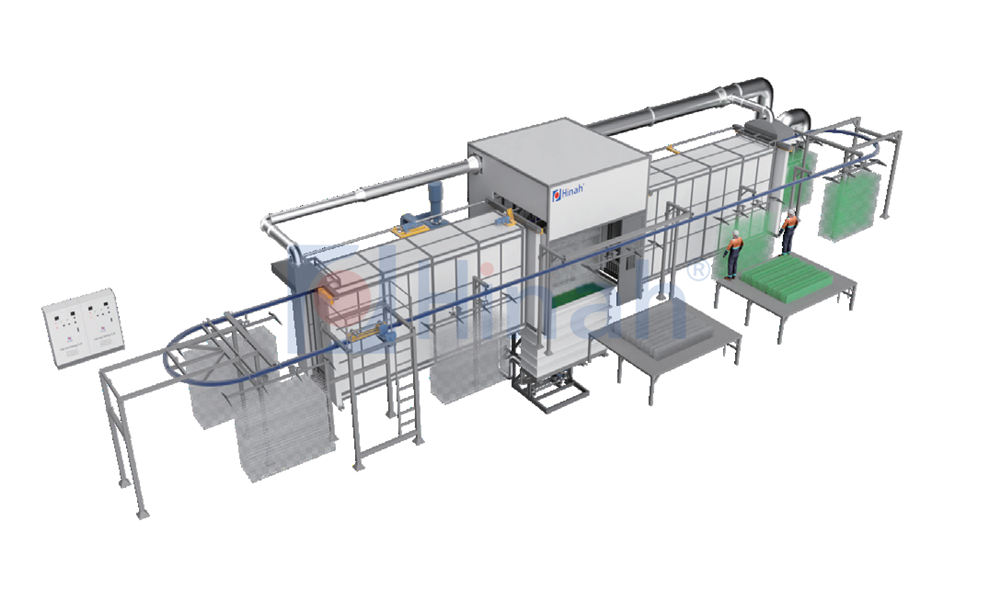

New Industrial Ovens: Major equipment manufacturers offer robust, high-capacity ovens designed for continuous production. These represent the highest end of the powder coating curing oven price spectrum but come with warranties, advanced features, and reliability.

Benchtop and Batch Ovens: Ideal for smaller shops or those working on smaller parts, these compact ovens are a popular entry point. They are widely available from industrial suppliers and are often electric.

Used and Refurbished Ovens: This can be an excellent way to acquire a high-quality coating oven at a fraction of the cost. However, it's crucial to inspect the oven's condition, especially the insulation, heating elements, and controls, to avoid costly repairs down the line.

Custom-Built Solutions: Many companies specialize in building ovens to a user's exact specifications, perfect for unique part shapes or specific workflow integrations.

Breaking Down the Powder Coating Curing Oven Price

The powder coating curing oven price is notoriously variable, with figures ranging from a few thousand dollars for a small benchtop unit to tens of thousands for a large walk-in system. Several factors dictate the cost:

Size: This is the most significant factor. Larger internal volumes require more materials, more powerful heating systems, and heavier-duty insulation.

Heat Source: Gas ovens typically have a higher purchase price than electric ovens of the same size but can save money over time through lower fuel costs.

Features: Advanced features like programmable logic controllers (PLCs), high-quality stainless steel interiors, data logging capabilities, and extra insulation will increase the price.

New vs. Used: As mentioned, a used powder coating curing oven for sale will be cheaper upfront but may carry hidden costs.

Delivery and Installation: Don't forget to factor in the cost of shipping a large, heavy item and any necessary electrical or gas hookup services from a licensed professional.

The DIY Route: What to Consider for a Powder Coating Oven Build

For many hobbyists and small startups, a DIY powder coating oven build is an attractive project to control costs. The most common approach is converting an old kitchen oven or building a cabinet from scratch using insulated panels.

Crucial tips for a successful build:

Safety First: This is paramount. You are working with high temperatures and electricity or combustible gases. All wiring must be done to code by a qualified electrician. The heating elements must be properly guarded, and the oven must have a reliable thermostat to prevent thermal runaway.

Material Selection: The interior must be made of metal. Never use wood, plastics, or materials that can off-gas or catch fire. Old refrigerators are not suitable as their insulation can be flammable.

Heat Source: For electric builds, oven heating elements from old appliances are a common choice. For gas, it is highly recommended to use a certified, commercially designed burner system for safety.

Ventilation: While not always required for curing, a small vent is often recommended to allow any fumes from the curing powder (though minimal) to escape.

A DIY powder coating oven build can be rewarding, but it requires significant research, mechanical skill, and a relentless focus on safety.

Beyond the Basics: Other Types of Coating Ovens

While the powder coating curing oven is our focus, the term coating oven can be broader. Some facilities use combination systems. For example, a coating oven might refer to a system used for liquid paint curing, which operates on similar principles but may have different airflow and filtration requirements to handle solvents. The core function of applying controlled heat remains the same, but the specific powder coating curing oven design is optimized for the unique properties of powder materials.

5 Common Problems with Powder Curing Ovens and How to Solve Them

Even the best equipment can have issues. Here are common problems encountered with a Powder Curing Oven:

Incomplete or Uneven Curing: This is the most frequent issue. Parts are tacky, the finish is soft, or it has an orange peel texture.

Cause: Incorrect temperature or time, poor airflow creating cold spots, overloading the oven, or a malfunctioning thermostat.

Solution: Verify oven temperature with a standalone oven thermometer. Ensure parts are spaced adequately for air circulation. Check that fans are operational and that vents aren't blocked.

High Energy Consumption:

Cause: Poor insulation, leaks around the door, or an undersized heating system working overtime.

Solution: Inspect door seals and replace if worn. For homemade ovens, add more insulation. Ensure the oven is appropriately sized for your typical workload.

Yellowing of the Finish:

Cause: Typically caused by overheating or the part being in the oven for too long. It can also be due to fumes from silicone or other contaminants burning off in the oven.

Solution: Pre-clean parts thoroughly to remove all oils. Pre-bake uncoated parts to burn off any contaminants beforehand. Precisely follow the powder manufacturer's time and temperature specifications.

Overcuring:

Cause: Excessive temperature or time can cause the powder to become brittle, discolor, or lose its mechanical properties.

Solution: Again, precise control is key. Calibrate your controls regularly and avoid the "a little longer for good measure" approach.

Contamination on the Cured Surface:

Cause: Dust, dirt, or grease inside the oven can fall onto parts or be circulated by the fans while the powder is still molten.

Solution: Maintain a clean oven interior. Regularly vacuum out any dust or powder debris. Avoid coating parts that are overly dusty or greasy.

Choosing, buying, or building a powder coating curing oven is a major decision that directly affects your finish quality and bottom line. By understanding the principles of powder coating curing oven design, realistically assessing the powder coating curing oven price, and being aware of potential problems, you can select the perfect powder coating curing oven for sale or successfully execute your own powder coating oven build. Whether you opt for a ready-made coating oven or a custom Powder Curing Oven, this investment, when chosen wisely, will serve as the cornerstone of your powder coating success for years to come.