Introduction to Powder Coating Equipment

Before understanding powder coating equipment, we need to know what powder coating is.

Powder coating is a process where powder coating equipment (electrostatic spray guns) applies powder paint to the surface of a workpiece. Under electrostatic action, the powder evenly adheres to the surface, forming a powdery coating. This coating is then cured at high temperatures, resulting in a final finish with various effects (depending on the type of powder used). Powder coating outperforms traditional liquid painting in terms of mechanical strength, adhesion, corrosion resistance, and aging resistance, though it is more costly.

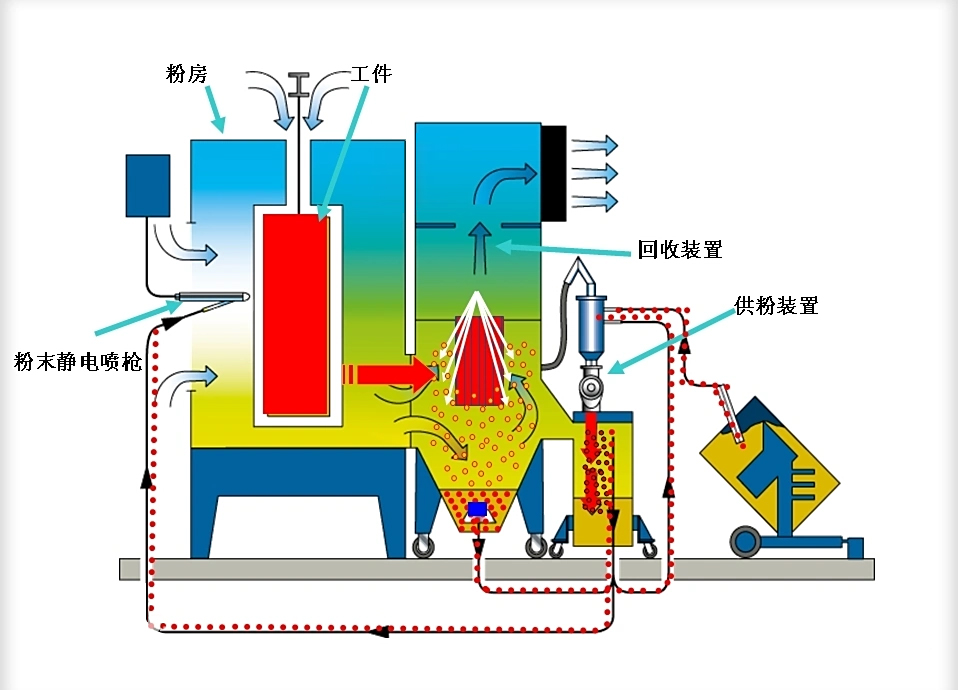

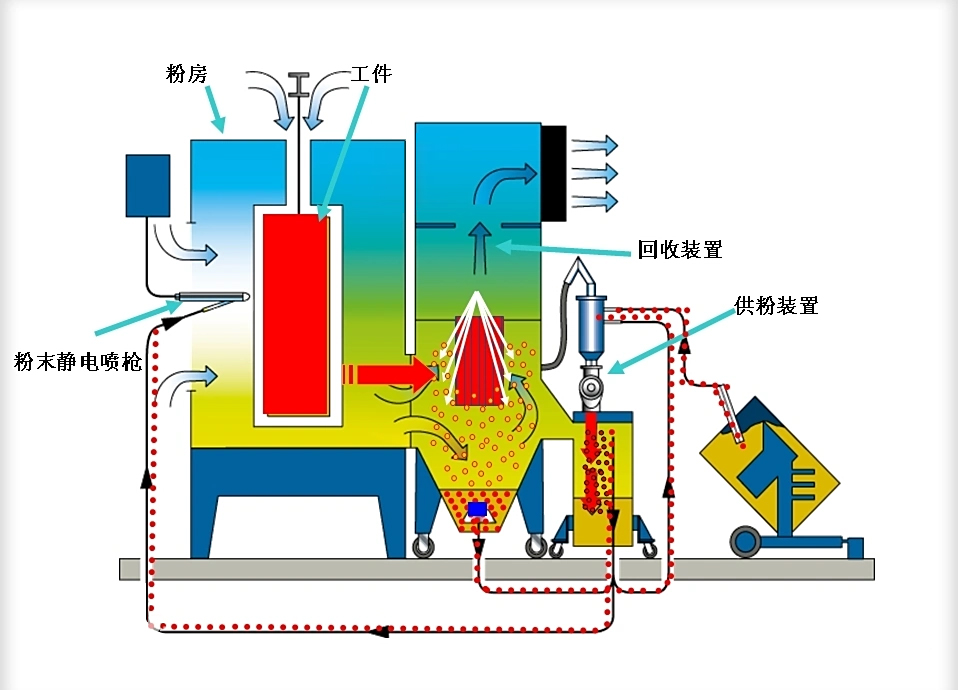

Powder coating equipment is a systematic industrial setup used for electrostatic powder coating processes, primarily in the surface treatment of metal workpieces. It operates on the principle of high-voltage electrostatic adsorption to ensure even powder application and recycling, offering strong environmental benefits and high powder utilization rates.

A powder coating system consists of an electrostatic spray gun, recovery unit, powder booth, and feed system, forming a closed-loop setup. The spray gun uses built-in high-voltage generators or corona ring technology to charge the powder, ensuring effective adhesion to the workpiece while overcoming the Faraday cage effect. The recovery system comes in two types: cartridge-based (for single-color applications) and cyclone-based (for multi-color setups), paired with PP/PVC powder booths to prevent environmental contamination. The feed system includes automatic sieving and fluidization, allowing for the mixing of new and recycled powder, achieving a utilization rate of 90%-98%.

Structure of a Powder Coating System

A complete electrostatic powder coating system mainly includes a powder feed unit, one or more electrostatic spray guns with control units, an electrostatic generator (usually integrated into the spray gun), and a powder recovery unit. The core components of powder coating equipment are:

Electrostatic Powder Spray Gun

Uses high-voltage static electricity to adhere powder to the workpiece surface, directly affecting transfer efficiency and film thickness control. Manual guns suit small-batch, high-variety production, while automatic guns are ideal for large-scale operations.

Powder Feed Unit

Supplies fluidized powder to the spray gun via compressed air, supporting long-distance transport (e.g., 50-foot hoses). Adjustable feed rates and atomization settings accommodate different coating thicknesses.

Typically, the feed unit consists of a powder hopper (containing the coating powder) and a sieve. Fresh powder can be added directly, while recovered powder is sieved to remove impurities before reuse.

Recovery System

Common types include cartridge-based and dual-cyclone systems. Cartridge-based recovery uses high-efficiency filters to reclaim over 99% of sprayed powder, offering simplicity and easy maintenance. Most single-color (or limited-color) users opt for this. Dual-cyclone systems are used in color-changing booths for faster transitions, making them ideal for frequent color-switching operations.

Powder Booth

Encloses the coating process in a controlled environment, preventing powder spillage and pollution while enabling recycling. Common materials include PP, PVC, and specialized Apogee. The sealed setup ensures containment and high recovery rates.

Control System

Integrates spray gun adjustments and recovery unit coordination for automated operation.

Powder Curing Oven

Uses high temperatures to level and cure the powder into a durable coating.

Key Features of Powder Coating Equipment

Efficiency: Single-pass film formation increases productivity by 30-40%.

Energy-saving: Reduces energy consumption by about 30%.

Low pollution: No volatile organic solvents (e.g., toluene, xylene found in liquid paints).

High material utilization: Over 95%, with recyclable powder.

Superior coating quality: Single-layer thickness of 50-80μm, with better adhesion and corrosion resistance than liquid paint.

High yield: Allows for re-spraying before curing. Common methods include electrostatic spraying and dip coating.

Leading Brands and Manufacturers of Powder Coating Equipment

1、Top Global Brands of powder coating equipment (No Particular Order)

GRACO (USA): Founded in 1926, a leader in fluid handling systems.

Gema (Switzerland): Part of Graco, specializing in electrostatic powder coating.

Wagner (Germany): Established in 1946, a global manufacturer of coating systems.

2、Reputable Chinese Brands of powder coating equipment (No Particular Order)

HANNA Technology: As a professional powder coating plant manufacturer, Hanna Technology (Hinah) provides professional powder coating plant and powder coating line equipment worldwide, such as automatic powder coating line, powder coating equipment with conveyor, painting line system, power and free conveyor, automated conveyor system, powder coating oven and booth, powder coating pretreatment, and other coating lines.

Spray Painting: Known for efficient, uniform coating of large surfaces like cars and machinery.

XinKaiSheng Coating: Focuses on eco-friendly, automated powder coating solutions since 2009.

Based on HANNA’s 30+ years of powder coating experience, here’s our advice:

- Form a cross-functional team for evaluation.

- Request detailed written proposals from suppliers.

- Conduct site visits to assess manufacturing and operational performance.

- Inspect details like materials, safety features, and build quality.

- Consider total cost of ownership (TCO), not just upfront price.

- Define contract terms clearly, including performance guarantees.

Key Considerations When Purchasing Powder Coating Equipment

1. How well does the powder coating equipment's capacity actually match our production needs?

Pain point:

Suppliers often advertise theoretical max capacity but ignore real-world limits like part shape, color change frequency, conveyor speed, and curing time.

Key questions:

Based on our most typical parts (size, weight, shape, material) and actual production pace (parts processed per hour/day), considering color changes (cleanout time), rework, and maintenance - what's the equipment's real sustainable output? Is there simulation data or case studies to back this up?

2. What's the true efficiency of powder utilization and recovery systems?

Pain point:

Powder cost is a major operating expense. Low utilization wastes material and increases environmental costs. Recovery system performance directly affects new powder ratios and coating consistency.

Key questions:

Under conditions like ours (part types, color changes), what's the actual measured powder utilization rate? At what recycled powder sifting rate and blend ratio with new powder can we still maintain quality (flow, gloss, color)? What's the maintenance schedule and cost for recovery systems (cyclone + filters)?

3. What's the detailed energy use breakdown and optimization options about powder coating equipment?

Pain point:

Curing ovens are energy hogs (gas/electric). Preheating, conveyors, air compressors, and booth ventilation also consume significant power.

Key questions:

Can you provide energy consumption data (kWh/m² or gas m³/m²) for each major component (oven, preheat, booth HVAC, air system, conveyor)? What specific energy-saving features (oven insulation, heat recovery, variable frequency drives, high-efficiency burners) suit our products? Any quantified energy savings?

4. Is pretreatment properly matched and prioritized?

Pain point:

Pretreatment (degreasing, rinsing, conversion coating, etc.) is foundational for coating adhesion and corrosion resistance, but suppliers often downplay it.

Key questions:

What specific pretreatment process do you recommend for our substrates (steel, aluminum, zinc) and performance needs (salt spray resistance)? How well does it integrate with the coating line (e.g., drying requirements)? How automated/costly are chemical management and wastewater treatment? Is pretreatment from the same supplier? How are responsibilities divided?

5. What's the powder coating equipment's reliability and parts availability?

Pain point:

Line downtime is extremely costly. Unreliable equipment or long lead times for critical parts (nozzles, high-voltage modules, PLCs) is a nightmare.

Key questions:

What's the mean time between failures/annual failure rate for this model? Brands/models of key components - how standardized are they? Are common parts stocked locally? Emergency parts lead time? Local technical support (number of engineers, response time)?

6. How is dust emissions control and regulatory compliance ensured about powder coating equipment?

Pain point:

Environmental regulations (VOCs, particulates) keep tightening. Booth leaks or inefficient recovery risk fines or shutdowns.

Key questions:

How does the equipment maintain negative booth pressure? What's the sealing design? Guaranteed exhaust dust concentration levels? Which specific emissions standards does it meet (provide codes)? Filter specs and replacement intervals? Online monitoring capability?

7. Are safety and explosion protections adequate about powder coating equipment?

Pain point:

Powder environments carry explosion risks. Safety is non-negotiable.

Key questions:

What explosion protection ratings (e.g., ATEX Zone) apply to booths/recovery areas? Explosion vent specs (size, location)? Spark detection/fire suppression? Grounding measures? Safety interlocks (like door switches)? Can you provide safety certifications?

8. How flexible and expandable is the powder coating equipment?

Pain point:

Product lines change and factories expand. Inflexible equipment becomes obsolete fast.

Key questions:

Is there room to extend line length/booth height/oven size later? Can spray gun setups adapt to different part sizes? Can controls be upgraded (MES interface, more I/O)? Compatibility with special powders (metallics, textures)? Would modifications be needed?

9. What does the powder coating equipment technical support and service include ?

Pain point:

Installation is just the beginning - long-term support is critical.

Key questions:

Warranty details (coverage, duration, response time)? Free support period and methods (phone, remote, onsite)? Onsite response time guarantee (12/24/48hr)? Preventive maintenance plans? Training scope/duration for operators vs technicians? Local service centers?

10. Can we get full cost analysis beyond purchase price about powder coating equipment?

Pain point:

Cheap equipment may have high operating costs (energy, powder waste, maintenance, downtime).

Key questions:

Can you provide a detailed 5-10 year total cost of ownership analysis including purchase, installation, energy, powder, maintenance, parts, labor, and potential downtime - comparing different options?

11. How user-friendly is operation and maintenance about powder coating equipment?

Pain point:

Complex equipment requires skilled labor, increasing costs.

Key questions:

How intuitive are daily operations (color changes, adjustments)? What's involved in routine maintenance (lubrication, cleaning) - frequency, time needed? Special tools/certifications required? Clear troubleshooting guides and user interfaces?

12. Can we verify the powder coating equipment supplier's industry experience?

Pain point:

Does the supplier really understand our sector's (furniture, appliances, auto parts, etc.) needs?

Key questions:

Can you provide 3 verifiable customer references with similar products/materials/volumes? How many systems have you installed in our specific industry? Experience with our particular challenges (complex shapes, high durability needs)?

13. How precise and repeatable are process controls about powder coating equipment?

Pain point:

Inconsistent coating thickness and curing hurt product quality.

Key questions:

How stable is gun voltage/current? Powder pump accuracy? Oven temperature uniformity (±°C)? Online thickness measurement or oven tracking? How does the control system ensure batch-to-batch consistency?

14. What hidden contract risks should we watch for when purchase powder coating equipment?

Pain point:

Vague acceptance criteria, unfair liability terms, or IP issues.

Key questions:

What specific performance guarantees (capacity, efficiency, quality) and penalties for missing them? Liability for delivery delays? Installation responsibilities? Software licensing/upgrade costs? Who owns custom design IP? How reasonable are force majeure clauses?

In summary

If you’re planning to purchase powder coating equipment or set up a production line, explore HANNA Technology’s offerings, including Powder Coating Line、Powder Coating Equipment、Painting Line System、E-Coating Line, and more. With 30 years of expertise and exports to 60+ countries, our solutions are tailored for efficiency and reliability. Click “powder-coating-plant” to learn more.