Washing Equipment

The diversity of washing equipment is immense, reflecting the vast range of items needing cleaning

Domestic/Laundry: Washing machines (top-loading, front-loading), dryers (often integrated as washer-dryers), dishwashers, sink-mounted units.

Commercial/Service: Industrial washing machines and dryers (for hotels, hospitals, laundromats), commercial dishwashers (undercounter, conveyor, flight-type), carpet extractors, pressure washers, vehicle wash systems (touchless, friction, self-serve).

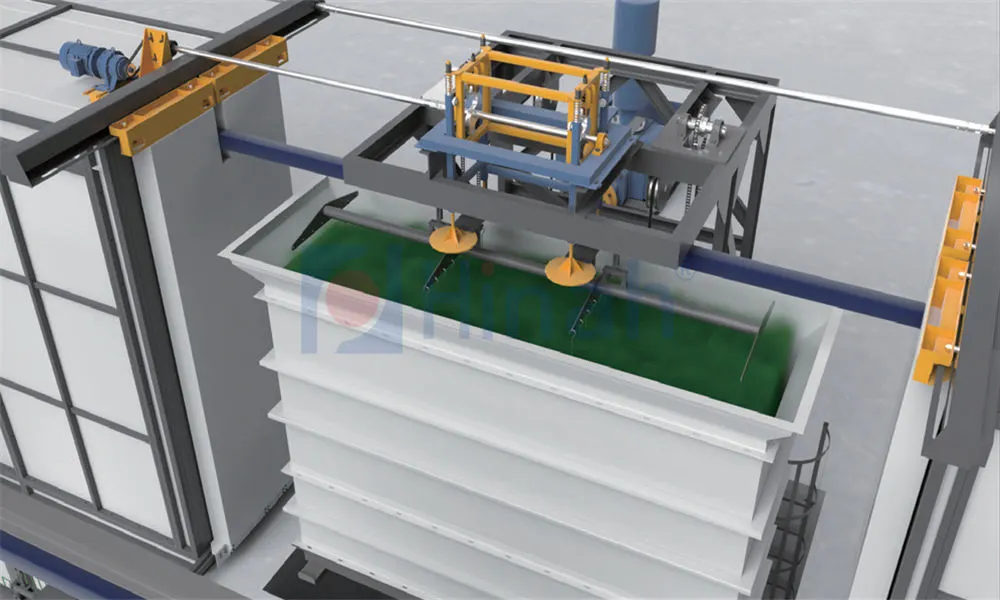

Industrial/Manufacturing: Parts washers (cabinet, immersion, ultrasonic, conveyorized), tank washers (CIP - Clean-in-Place systems), barrel washers, specialized systems for electronics, optics, or aerospace components.

Food & Beverage/Pharmaceutical: Highly specialized CIP and SIP (Sterilize-in-Place) systems designed for stringent hygiene and sterilization requirements within processing lines and tanks.

Modern washing equipment increasingly incorporates advanced features for efficiency and user control. Automation is key, with programmable cycles for different fabrics, soil levels, or materials. Sensors monitor water levels, temperature, turbidity (soil load in water), and even load size to optimize resource usage. Digital controls provide user-friendly interfaces and customization. Crucially, water and energy efficiency have become paramount design considerations, with technologies like heat recovery, variable-speed drives, low-water wash systems, and optimized cycle times reducing environmental impact and operational costs.