The fundamental principle is the closed-loop control cycle of Electronic Control System

Sensing: Dedicated sensors (e.g., temperature probes, pressure transducers, position encoders, cameras) continuously gather data about the system's current state or environmental conditions.

Processing: This raw data is fed into an electronic controller (like a microcontroller, PLC, or dedicated ECU). The controller compares the sensed values against a predefined setpoint or desired target value using programmed logic or algorithms (e.g., PID control).

Decision & Command: Based on the comparison (the "error" signal), the controller calculates the necessary corrective action.

Actuation: The controller sends electronic signals to actuators (e.g., motors, solenoids, valves, heaters, displays) which physically alter the system to drive it towards the desired state.

Feedback: The sensors continuously monitor the results of the actuation, feeding new data back to the controller, closing the loop and enabling continuous, dynamic adjustment.

Key Advantages over Mechanical/Hydraulic Systems of Electronic Control System

Precision & Accuracy: Enables extremely fine-grained control unattainable mechanically.

Flexibility & Adaptability: Control logic can be easily reprogrammed via software for different tasks or conditions without hardware changes.

Complexity Handling: Capable of managing intricate multi-variable systems and sophisticated algorithms (e.g., engine management, flight control).

Efficiency: Optimizes performance, reduces energy consumption, and minimizes waste.

Diagnostics & Connectivity: Built-in self-diagnostics, data logging, and communication capabilities (CAN bus, Ethernet, wireless) for monitoring, remote control, and integration into larger networks (IoT).

Miniaturization & Integration: Allows complex control functions within compact devices.

Ubiquitous Applications of Electronic Control System

Automotive: Engine Control Units (ECU), Anti-lock Braking Systems (ABS), Electronic Stability Control (ESC), climate control, infotainment.

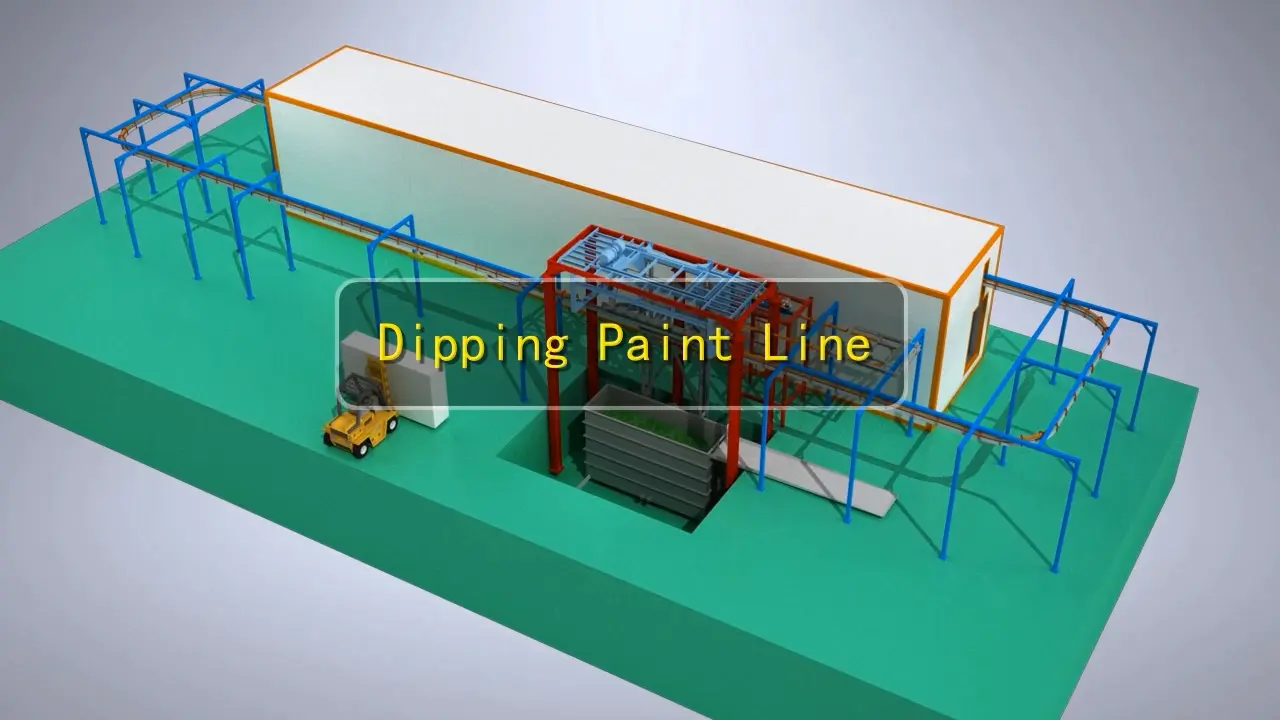

Industrial Automation: Programmable Logic Controllers (PLCs) managing robotic arms, assembly lines, process control (chemicals, refining), CNC machines.

Consumer Electronics: Smartphones, washing machines, refrigerators, air conditioners, cameras.

Aerospace & Defense: Fly-by-wire aircraft control, missile guidance, avionics.

Medical Devices: Pacemakers, infusion pumps, ventilators, diagnostic equipment.

Building Management: HVAC control, lighting systems, security systems.

Energy: Smart grid management, renewable energy systems (solar/wind turbine control).

Evolution: ECSs have evolved from simple analog circuits to sophisticated digital systems incorporating microprocessors, powerful algorithms (including AI and machine learning), and extensive networking capabilities. Modern ECSs are increasingly intelligent, predictive, and interconnected, forming the nervous system of smart devices, factories (Industry 4.0), and critical infrastructure.