- Powder Coating Line

- Powder Coating Equipment

- Painting Line System

-

E-Coating Line

- Monorail E-Coating Line

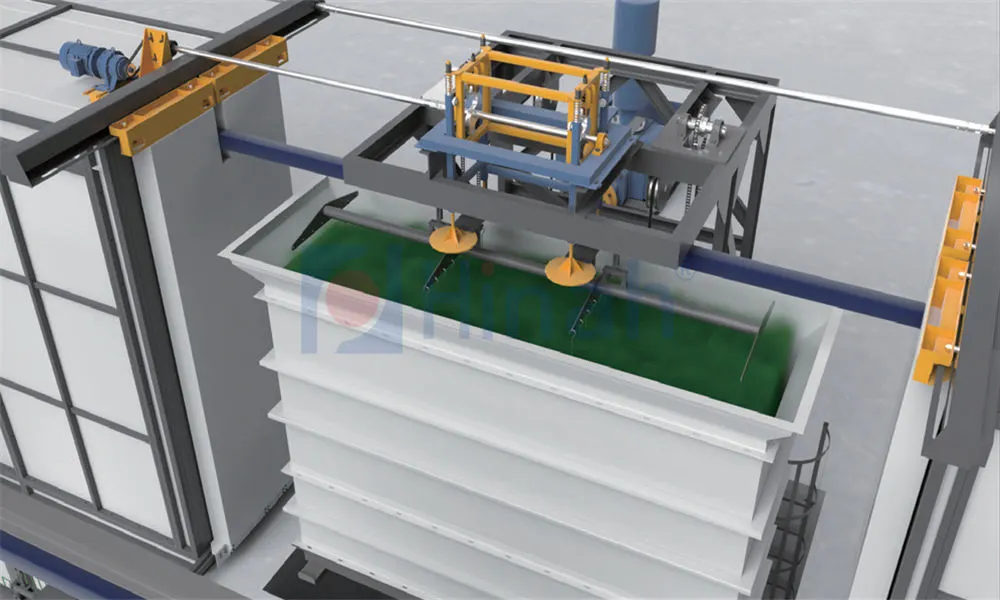

- Gantry Stepping E-Coating Line

- Accumulation Conveyor E-Coating Line

- Trolley Hoists E-Coating Line

- E-coating System Accessories

- Aluminum Products E-coating Line

- Automotive Body E-coating Line

- Automotive Parts E-coating Line

- Small Electric Cars E-coating Line

- Power Moto Tricycle E-coating Line

- Electric Appliances E-coating Line

- Castings E-coating Line

- Stainless Steel Products E-coating Line